Waste Water Heat Recovery for Showers

How to model WWHRS as part of passive design analysis for BREEAM credit Ene 04

Recoup have recently worked with a UK Low Carbon Consultant, who was undertaking a passive design analysis for a new build hotel, and looking to incorporate Waste Water Heat Recovery Systems (WWHRS) for showers to help achieve a credit in Ene 04 for the BREEAM UK New Construction 2014 scheme.

BREEAM for New-build

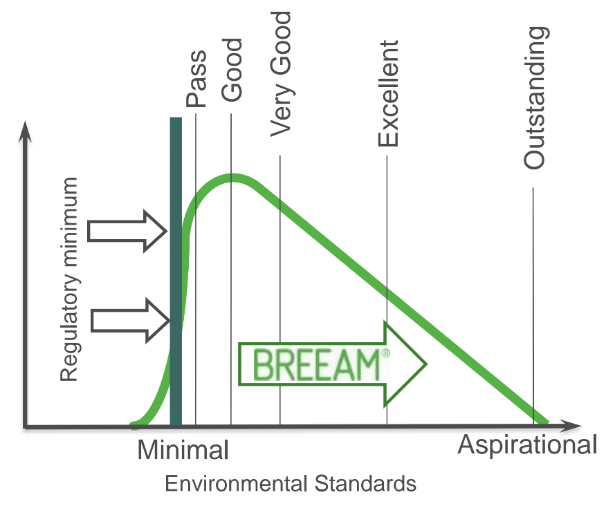

For anyone who doesn’t know, BREEAM is the longest established and most widely used 3rd party certification scheme, designed by BRE to drive innovation and standards above the regulatory minimum. Most modern BREEAM projects are typically designed to achieve ‘Very Good’ and ‘Excellent’ ratings, although increasingly more new-build designs are aspiring to the challenge of achieving the BREEAM ‘Outstanding’ rating.

The BREEAM assessment process is comprised of two stages: The Design Stage (interim) and the Post-Construction Stage (Final), and within these stages, there are a number of assessment sections. The Energy Section aims to encourage the design and operation of energy efficiency buildings, driving energy efficiency, and sustainable energy use; and ultimately reducing CO2 emissions.

For projects where there is to be significant shower use, such as residential developments or apartments; hotels or student accommodation; or sports and leisure facilities, WWHRS can contribute towards BREEAM credits within the Energy section, and in particular, credits for ENE04: Low or Zero Carbon technologies (LZC), where: a ‘meaningful reduction in regulated carbon dioxide’ must be demonstrated to contribute towards a BREEAM credit, and while the amount of energy or CO2 emissions reduction is not specified (in Ene 04), it should not be a trivial amount. As a guide, the installation should contribute at least 5% of overall building energy demand and/or CO2 emissions.

Unlike the Ene 01 – Reduction of energy use and carbon emissions (which is focused on demonstrable and robust performance improvement), Ene 04 – Low carbon design aims to encourage project teams to consider a particular design approach to minimise the reliance on active building services systems.

LZC Feasibility Modelling of WWHRS for a Hotel Design, Ene 04 Credit.

The hotel design we assessed, has 160no bedrooms all with en suite shower facilities. The guest bedrooms are over five floors (2-6) and the floor plan on each level is essentially the same layout. Service risers are located, in most cases, between adjoining bathroom pods.

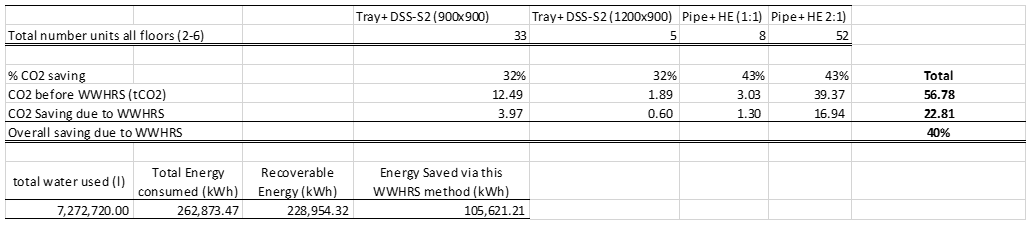

In order to initially quantify the savings that could be achieved by utilising WWHRS, Recoup made an assessment of the supplied floor plans, and modelled a number of WWHRS scenarios. Following some discussion with the Energy Assessor, we then produced an energy savings calculation model for an agreed WWHRS design, that utilised agreed assumptions based on the building type and the DHW load. The overall energy consumption was calculated from the dynamic simulation model utilising the National Calculation Methodology (NCM) for the specific building usage profile (see more information here).

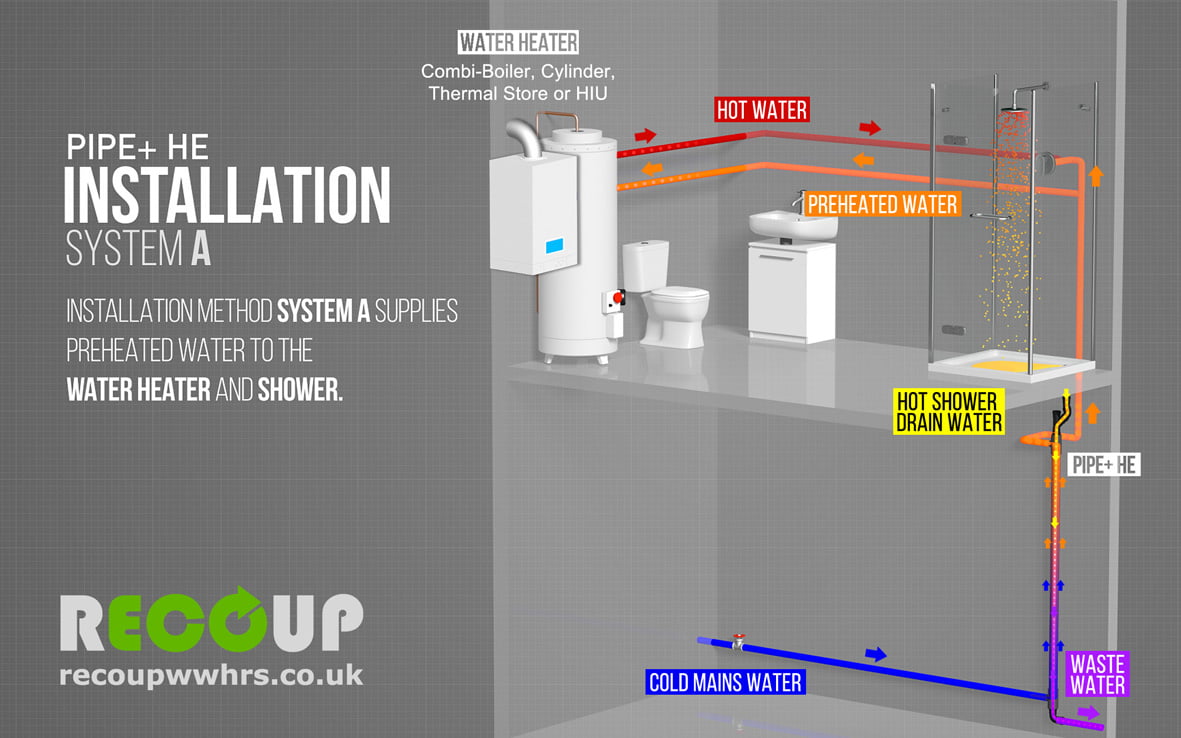

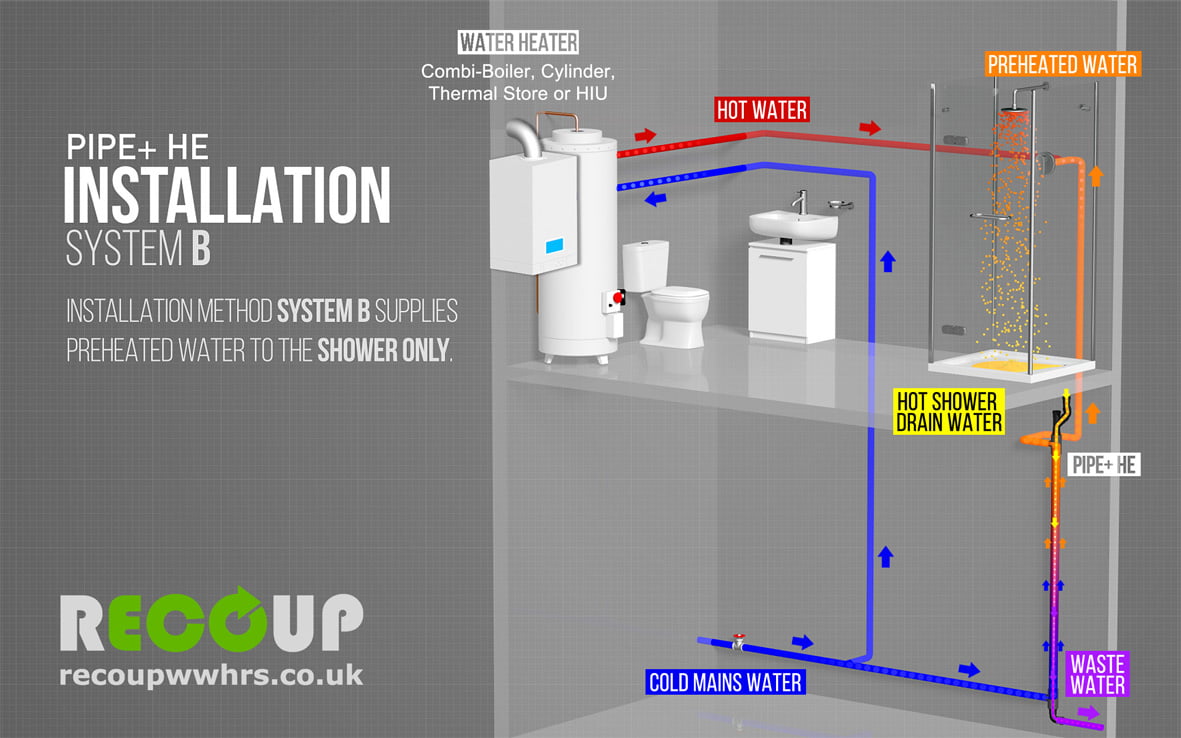

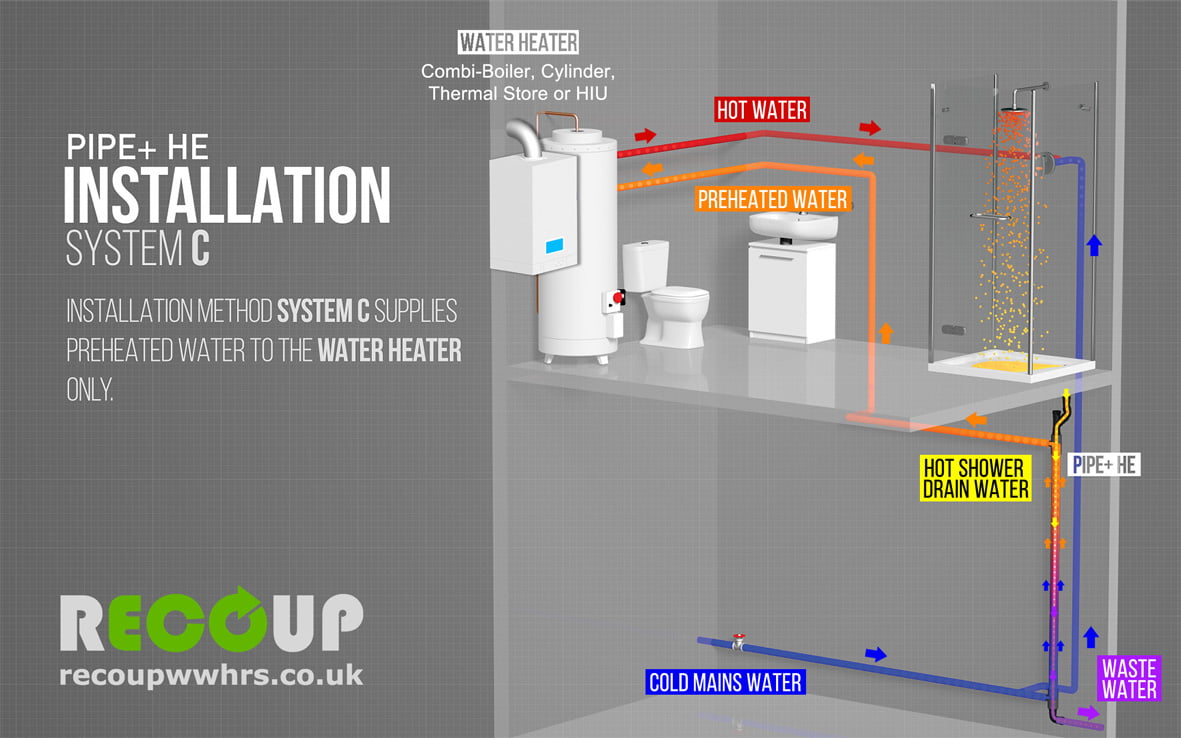

As you can see from the table above, the saving due to WWHRS is calculated to be 22.81 tCO2 pa. This represents a combined saving of 40% across all showers (a mix of vertical and horizontal WWHRS units installed as System B). Importantly, in the case of this BREEAM assessment, 22.81 tCO2 contributed to >5% savings against the baseline CO2 emissions for the building as designed, which qualified for a credit under the Ene 04 BREEAM issue.

Confused over how to incorporate WWHRS into SBEM? See this article.

WWHRS for Showers

Of course, as well as design credits and compliance, WWHRS has the advantage of offering passive, instantaneous hot water savings, which reduce both energy costs & CO2 emissions, but also peak DHW demand, and therefore potentially DHW plant size and associated costs.

WWHRS is simple to design in and install, and can generate significant DHW energy reductions for almost any building where showers are used. Furthermore, it requires no complex installation or commissioning; no ongoing or planned maintenance; no end-user interaction or behavioural changes; and has no moving or mechanical parts; and no consumables or filters to change – Just on-demand, passive energy savings with every shower.

If you want to know more, or get help or advice with your current commercial or residential design projects, please contact us.