Waste Water Heat Recovery for Showers

The Lovell Tomorrow Home featuring Recoup Pipe HEX

Recoup’s shower waste water heat recovery system (WWHRS), the Recoup Pipe HEX, has been included in another leading housebuilder trial. This time for Lovell as part of its eco-friendly comparison trial at Cornish Park in Spennymoor, Durham.

The research project, which started in August 2024, features three houses incorporating the latest innovations in green technology. Two provide a comparison, with one featuring an Air Source Heat Pump (ASHP) and separate hot water cylinder and the second an Infrared All-electric Heating System with hot water provided by a dedicated ASHP cylinder. The third house acts as ‘control’ to compare and monitor the impact of the individual technology. The eco-homes will help inform Lovell on the specification of future home development as the business moves to the proposed 2025 Future Homes Standard and beyond.

The Lovell Tomorrow Homes Project

Working with Teesside University, Lovell allocated two homes to provide the required data for research. The three-bedroom dwellings, which are based on the housebuilder’s ‘Cornish’ semi-detached design, are part of a wider scheme of 124 properties currently selling from the last phase of the project on Cornish Park, in Spennymoor.

Teesside University and the Net Zero Industry Innovation Centre has been collecting data from both demonstrator homes, monitoring their performance in use, using metrics including operating costs and embodied/operational carbon figures to assess how the Tomorrow Home performs against other green technologies.

Lovell partnered with Thirteen Housing Association on the development to make a range of 2, 3 and 4-bedroom homes available for shared ownership. The trial homes will continue under the scheme once complete.

Lovell National Sales Director, Justine Elliott, said:

“As a responsible business, we are driving our emissions down year on year and are constantly looking at innovative ways we can do this, while continuing to deliver much-needed, multi-tenure homes across the UK.

“Collecting and sharing data is massively important here. Thanks to our partnership with Teesside University, we are able to measure the performance of alternative electric heating systems and various other new-to-market technologies, so we can gain valuable insight and continue innovating, as we plot a path to net zero.”

*Source Unlock Net Zero

Recoup’s Pipe HEX WWHRS Features in the Research

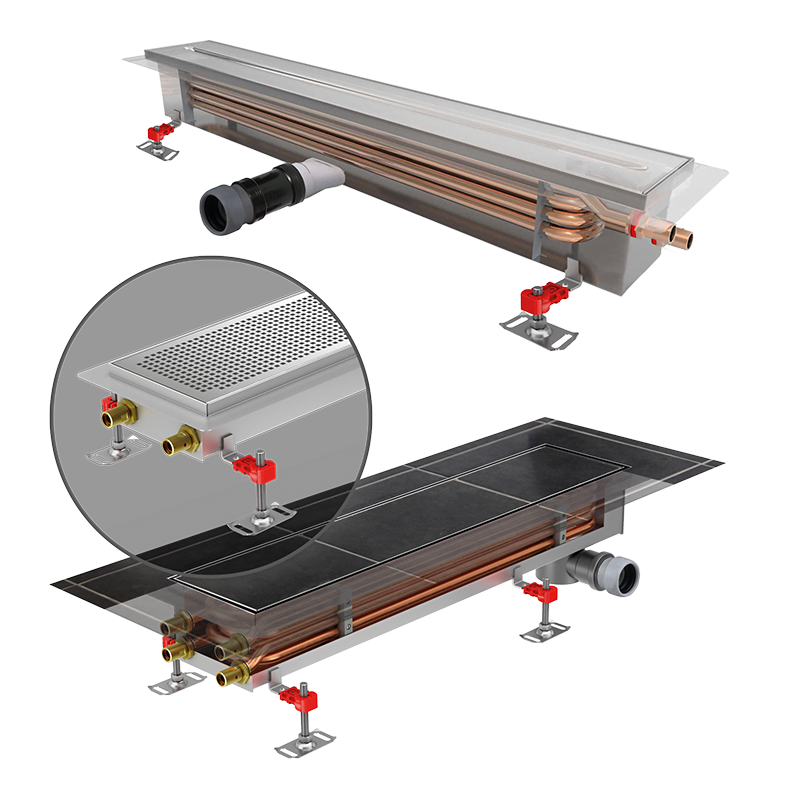

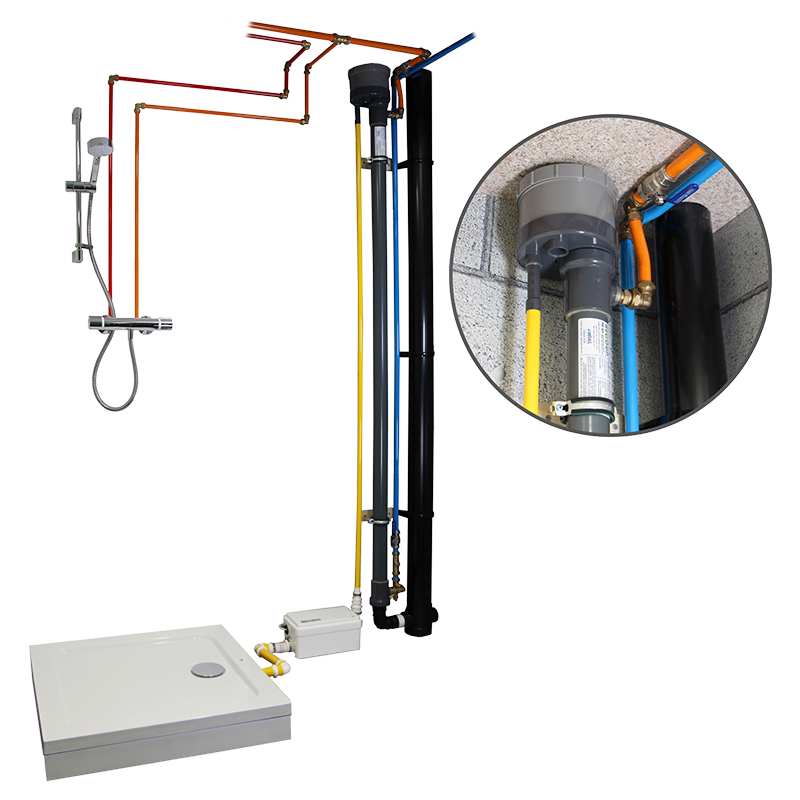

The research project incorporates various sustainability-focused elements into the build, providing data on the effectiveness of the range of energy systems. As part of the research, Recoup’s most efficient WWHRS system, the Recoup Pipe HEX, was installed in plot 65 Tomorrow Home alongside the Eco Heatwave infra-red heating system and Atlantic Calypso air source hot water cylinder. The Pipe HEX also features in plot 66 to work alongside the Daikin ASHP system with a direct hot water cylinder. Other technologies included solar PV, battery storage, and triple-glazed PVCu windows are included across the two properties.

Left to right: Dr Sean Williams (Teesside University), Elena Imani (Teesside University), Justine Elliott (Lovell), Iain Gillies (Lovell) and David Atkinson (Lovell). *Source Unlock Net Zero

“Lovell chose WWHR for the Tomorrow Home project as we see it as an important technology for reducing DHW demand,” said Iain Gillies Divisional Design & Innovation Manager. “We believe that it will be an integral part of our Future Homes Standards specification as we transition toward Net Zero.”

“As the building’s fabric is improved and heat loss reduced, domestic hot water becomes the largest demand for energy. Such is its efficiency and performance in SAP, WWHR has actually become part of the Lovell 2021 Building Regulations group specification as standard. We hope to be able to monitor the effects WWHR has reducing the energy requirements to heat domestic hot water in the next phase of our occupied live-in trials at the Tomorrow Home over the next year. We will be keen to see how it performs with both ASHP’s and air-sourced cylinders.’’

Ellis Maginn, head of technical & specification talks about the Tomorrow home project

How does WWHRS work with Combined ASHP and DHW Cylinders?

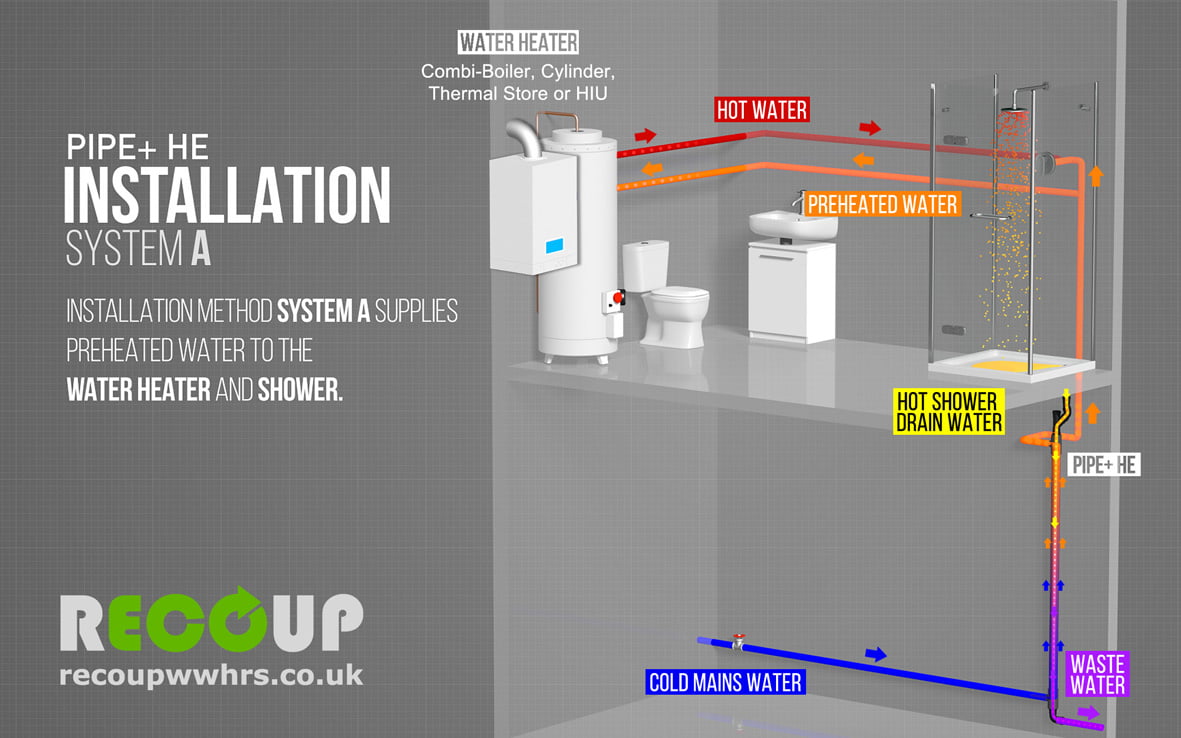

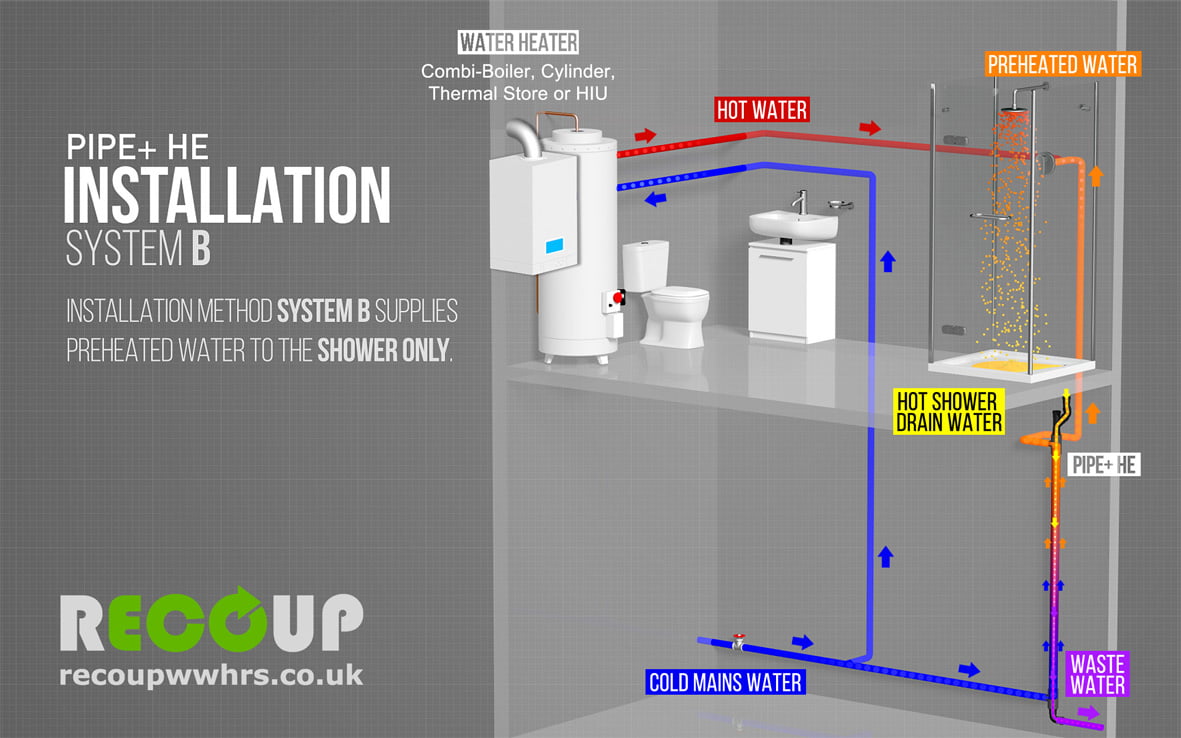

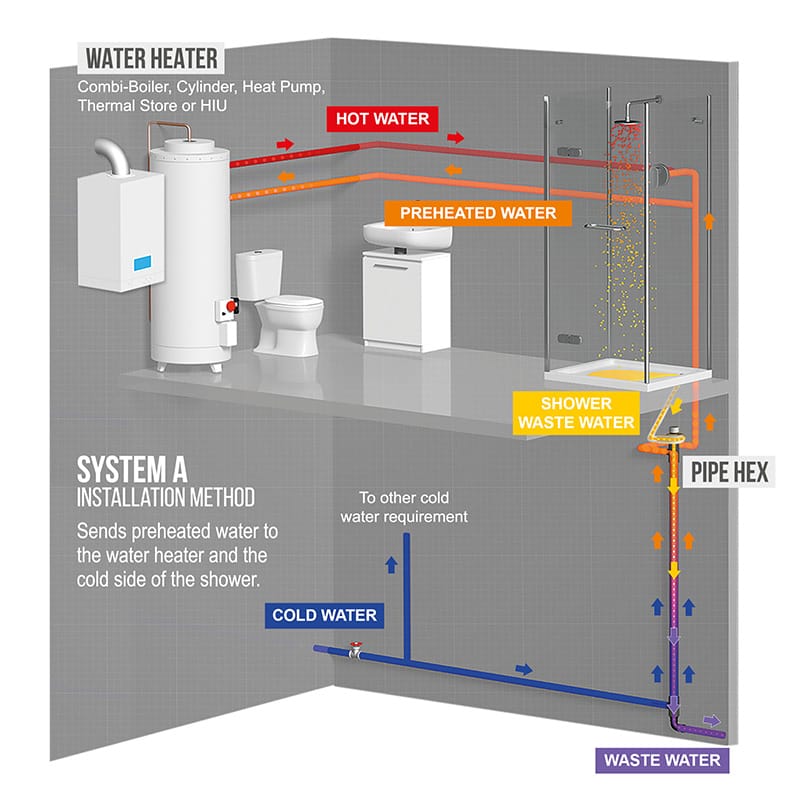

WWHRS works both compatibly and compliantly with any domestic ASHP system. An air source heat pump, often called an air-to-water source heat pump, heats homes by transferring heat from the outside air to water, which is then used through radiators and underfloor heating. The heat pump can also heat water stored in an air source hot water cylinder, which provides hot water for use from the taps, showers, and baths.

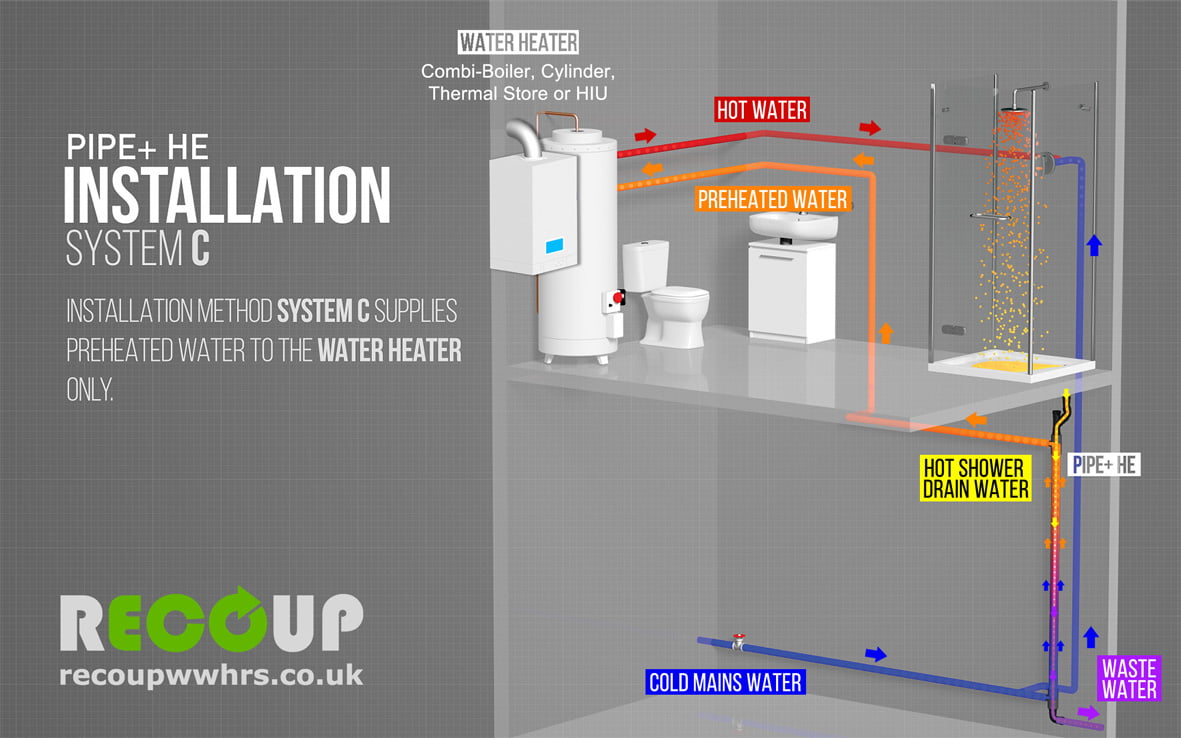

For additional energy efficiency and to increase SAP points, WWHRS can be used to support the production of domestic hot water (DHW) from the air source heat pump cylinder to generate energy-efficient hot water, while significantly reducing the DHW demand on the cylinder per shower use. The Recoup Pipe HEX was designed to reduce the overall energy requirement from showering by 60%, which naturally reduces the volume of hot water the ASHP is required to produce after each shower incident.

How does WWHRS work with Dedicated ASHP Cylinders?

Infrared (IR) heating is another innovative, low-carbon alternative for smarter and greener heating systems to replace gas boilers or ASHP ‘wet-heating’ radiator systems in smaller homes or apartments. Infrared heating panels are not necessarily a new technology, but the Tomorrow Home uses Eco Heatwave: a revolutionary thin film carbon infrared heating system which actually installs behind the plasterboard in the ceiling. This innovative, low aesthetic impact system is, however, designed for space heating only and so cannot be used for water heating. Therefore, a dedicated ASHP cylinder system is typically used with IR systems to produce energy-efficient hot water.

In most cases, a dedicated ASHP system offers a higher COP (Coefficient of Performance) than a combined ASHP system, which has to provide for both space and water heating needs. A feat that can be particularly demanding during the winter heating season. Again WWHRS can be simply and cost-effectively included as part of the DHW system.

The Recoup Pipe HEX installed on this plot was piped up to both reduce the hot water demand for each shower use, as well as to preheat the cold water main (CWM) feed to the ASHP cylinder, promoting higher efficiency, and thus increasing COP. This reduces the cylinder recharge time vs a system without WWHRS.

Atlantic Calypso air source hot water cylinder

“The key aims of this trial is to compare the two main contenders for space and domestic hot water heating directly against each other to inform our Future Home Standard specification,” Iain Gillies added.

“We will be assessing both systems on the three pillars of Regulations compliance, build cost and customer experience in terms of performance and running costs. We want to ensure that the homes we build are heated efficiently using the optimal balance of technologies. We are excited to be able to gain real world data and get post occupancy feedback to ensure that we are meeting customer’s needs. It will be particularly interesting to see how behaviours are affected by how the different heating systems work. We also need to ensure that we can provide our customers with sufficient hot water throughout the year.’’

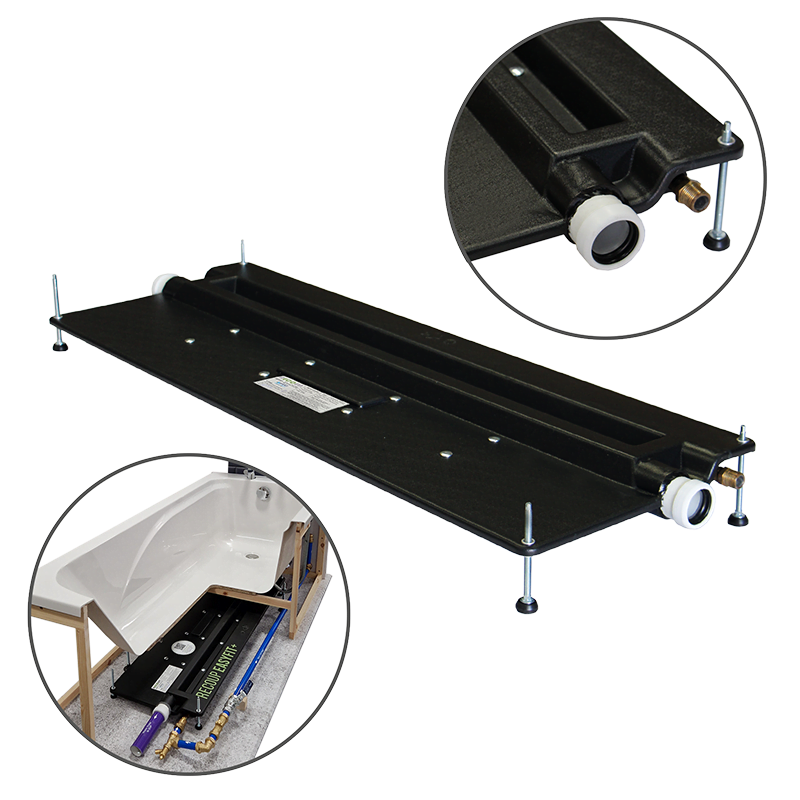

Working with Lovell

Recoup Energy Solutions has been providing WWHRS technical and specification support to Lovell since 2017. Initially, this support was directed at properties that needed to improve SAP, but with the introduction of Part L building regulations, this has expanded to more Lovell house types. The carbon and energy reduction targets introduced mean that both the Recoup Pipe HEX and Easyfit+ WWHRS products can significantly contribute to achieving compliance in even more new build homes, hence why Lovell continues to specify waste water heat recovery for showers in its developments throughout the UK.

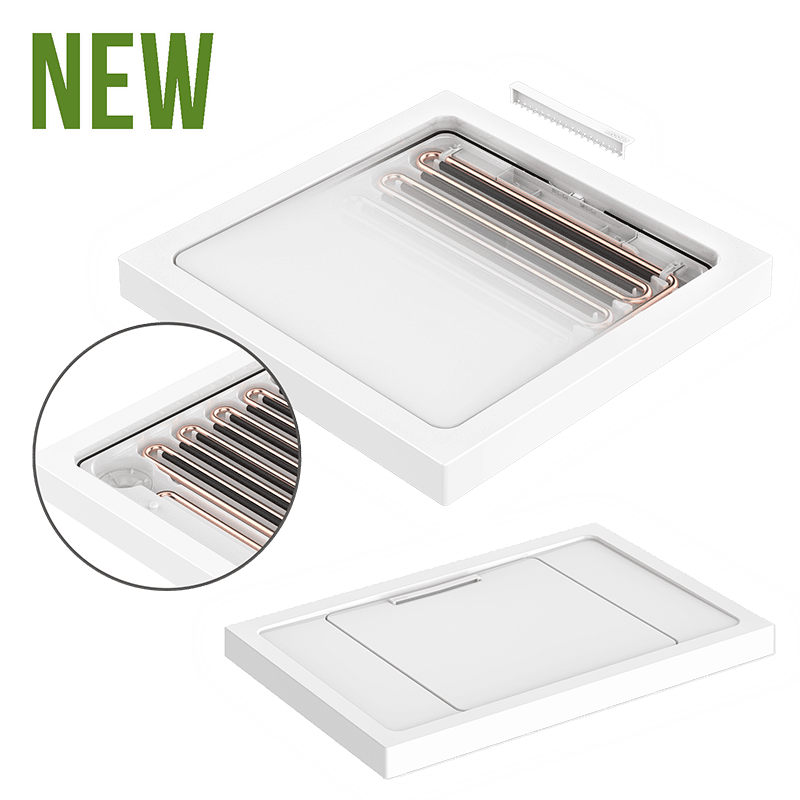

The introduction of the Recoup HeatDeck™ WWHRS integrated shower tray and Mira Heatloop™ WWHRS compatible electric showers, that are currently being considered by the Lovell technical teams, could provide further options to achieve energy-saving and carbon reduction goals. Whilst also benefiting the homeowner with no planned maintenance, no change of use, and lower household bills.

To learn more about how Recoup WWHRS can benefit your next new build or social housing development get in touch by email at info@recoup.co.uk or call us on 01379 844010.

More Case studies

Recoup Pipe+ HE chosen again for Gusto Homes’ second phase

Passively Recovering Waste Heat Energy With Every Shower Located in North Carlton, Lincoln, Phase two of Gusto Homes Woodlands Edge development consists of 6 two-storey passive solar homes set in 12 acres of parkland. With cutting-edge design and a holistic approach...

WWHRS for Granton Harbour, Edinburgh: 132 dwellings for Link Housing Association

Passively Recovering Waste Heat Energy With Every Shower A £20 million waterfront residential development designed by Mosaic Architecture + Design, for Link Housing Association, has confirmed specification of Recoup's WWHRS in the form of the Tray+ DSS-S2: our WWHRS...

BIM World case study feature on Recoup WWHRS and Barratt Developments

Passively Recovering Waste Heat Energy With Every Shower Passively Recovering Waste Heat Energy With Every Shower Passively Recovering Waste Heat Energy With Every Shower The below article has been taken from the BIM World case study feature written by...