Waste Water Heat Recovery for Showers

Double Walled vs Single Walled wwhrs Heat Exchangers

The UK market for Waste Water Heat Recovery Systems (WWHRS) is set for exponential growth within the new-build residential sector as the new Part-L 2021 and Future Homes Standard 2025 regulations come into force. Innovative new products, as well as new product entrants are and will continue to be seen in the coming years. Therefore, it is important to understand if the new entrants are built around single-walled heat exchanger technology rather than double-walled and the associated regulation requirements.

So, what are double walled and single walled heat exchangers, and why are they an important consideration when specifying or installing WWHRS?

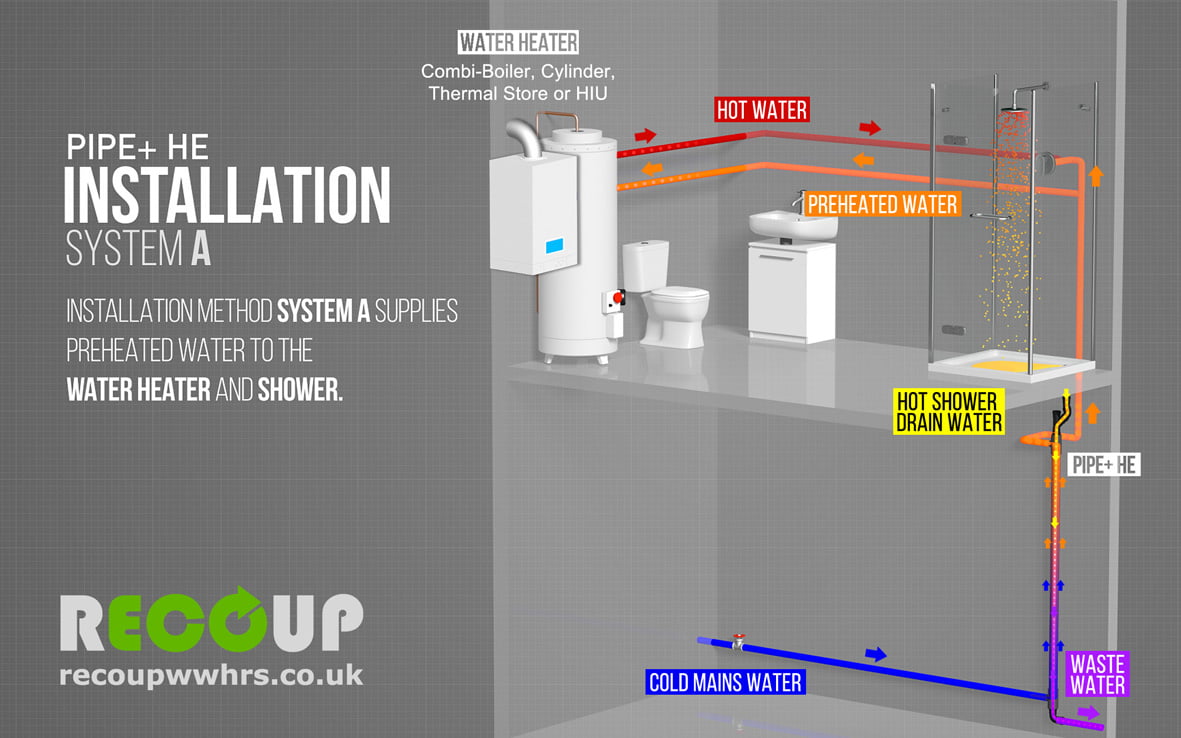

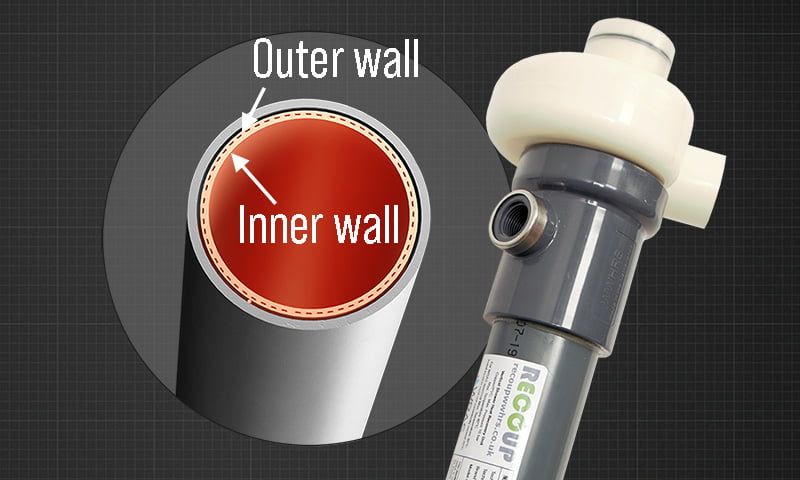

Double-walled and single-walled refer to the number of walls or layers that separate waste (drain) water and fresh potable (drinking) water and in the manufacture of a WWHRS this refers to the heat exchanger element of the technology. Predictably, single walled exchangers are produced from a single length of pipe, and is generally thinner than a double-walled exchanger and therefore can be consequently less robust. Copper is the ideal material for the heat exchanger due to its ability to its high capacity to conduct heat. Stainless steel is another material that can be used and in single walled exchangers can offer a greater rigidity, however, this comes at the expense of heat transfer efficiency. Currently the highest efficiency steel based WWHRS exchanger units are around 8-9% less efficient than the best double-walled system like the Recoup Pipe HEX.

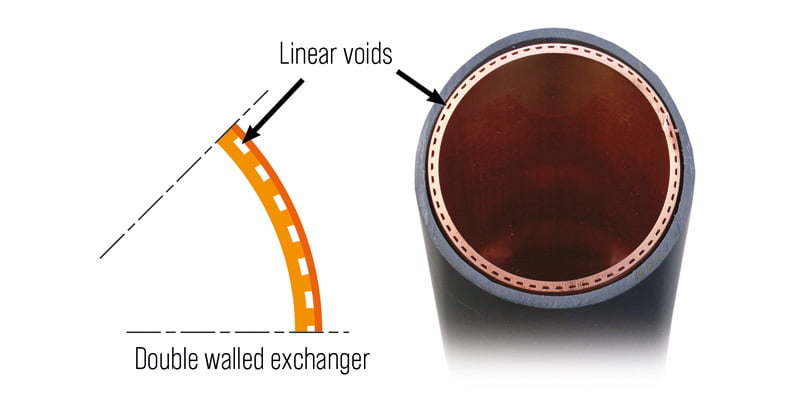

Double-walled exchangers are predominantly made from copper and formed via a mechanically pulled pipe-through-pipe process. This results in a seamless internal join that allows for near perfect internal heat exchange and a more robust construction than a single walled version. All Recoup double-walled exchangers are designed with small internal linear voids that run the length of the exchanger. These voids act to direct either the shower waste or mains water to the end of the exchanger if one of the walls fail (which is extremely unlikely). This shows as a leak indicating that there is a fault and identifying it to the user before any contamination takes place.

The BS EN-1717 regulation covers the “Protection against pollution of potable water in water installations and general requirements of devices to prevent pollution by backflow”.

The regulation states that any fluid of category 4 or 5 must be separated by a double wall in order to comply. It is generally accepted (but debateable) that the change of fluid category associated with showering is at the point of the trap for the shower where it passes from its lowest possible category of 3 to a category 5 fluid on joining the rest of the waste system. There are certainly some circumstances where the shower waste itself prior to the trap may be deemed as a category 5 fluid.

Therefore, in order for a single walled product to comply, additional design and installation requirements are required.

The primary implication of this it that a drainage trap must be installed downstream of the unit, and therefore a trap should not be installed before the WWHRS. Removing the trap from the normal position at the bath or shower tray, and then relocating it downstream of the WWHRS unit (often on the floor below the shower or bathroom), can present several significant issues to both the installer and homeowner:

The regulation states that any fluid of category 4 or 5 must be separated by a double wall in order to comply. It is generally accepted (but debateable) that the change of fluid category associated with showering is at the point of the trap for the shower where it passes from its lowest possible category of 3 to a category 5 fluid on joining the rest of the waste system. There are certainly some circumstances where the shower waste itself prior to the trap may be deemed as a category 5 fluid.

Therefore, in order for a single walled product to comply, additional design and installation requirements are required.

The primary implication of this it that a drainage trap must be installed downstream of the unit, and therefore a trap should not be installed before the WWHRS. Removing the trap from the normal position at the bath or shower tray, and then relocating it downstream of the WWHRS unit (often on the floor below the shower or bathroom), can present several significant issues to both the installer and homeowner:

- Traps are a common area for blockages; the trap would need to be easily accessible at the bottom of the exchanger, which for a vertical pipe WWHRS would be on the floor below the shower room and through the base of any boxing.

- If the trap does block, draining a vertical exchanger (usually over 2m long) is very problematic once installed.

- Additional shower noise could be generated internally from falling water going down the WWHRS unit and hitting the retained water in the trap at the base of the exchanger.

- Popular low-profile shower trays usually have integrated shower traps. A trap at both ends of a WWHRS exchanger will create an air block between them. Either low-profile shower trays cannot be used, the trap needs to be removed from it, or additional venting needs to be designed into the installation to prevent the air block occurring.

- The install height required to accommodate the trap, connectors, and any venting is very likely to increase, significantly in some situations. With the more efficient, longer, vertical exchangers this is very likely to cause installation issues in rooms with standard ceiling heights.

These restrictions, costs, additional design and installation considerations, and possible future problems can simply be avoided by selecting a WWHRS system that has a double walled heat exchanger. The overall costs and possible future implications of the installation will be lower and end users can have greater peace of mind with the product that has been installed.

Waste Water Heat Recovery for Showers (WWHRS) is becoming a much more familiar solution for the housebuilding, retrofit, energy saving, and sustainability sectors. With the inclusion of it within the notional building for the 2021revised Part L of the building regulations this is set to increase further. Therefore, the implications of using a single walled exchanger on the associated design and installation process and costs, should be considered to the same extent as the efficiencies, utilisation factor in SAP, and product costs

All Recoup WWHRS products (Pipe HEX range, Easyfit+ and Drain+ range) are built using double-walled heat exchangers that meet BS EN1717 requirements. This provides the best level of protection and peace of mind for all users. Contamination between waste (drain) water and fresh potable (drinking) water is protected against, the design and installation processes are easier and less costly, and there is no requirement for any planned product servicing and maintenance.

Visit our product pages for more information on all of the Recoup WWHRS double walled heat exchanger products.

The Recoup Knowledge Base is our fully searchable library of information available 24 hours a day. Quickly find answers to common questions or deep-dive full in-depth technical articles, product information and design walk-thrus, as well as, key articles, industry news and a growing list of case studies.

Visit Recoup Knowledge Base.