Waste Water Heat Recovery for Showers

What is WWHRS?

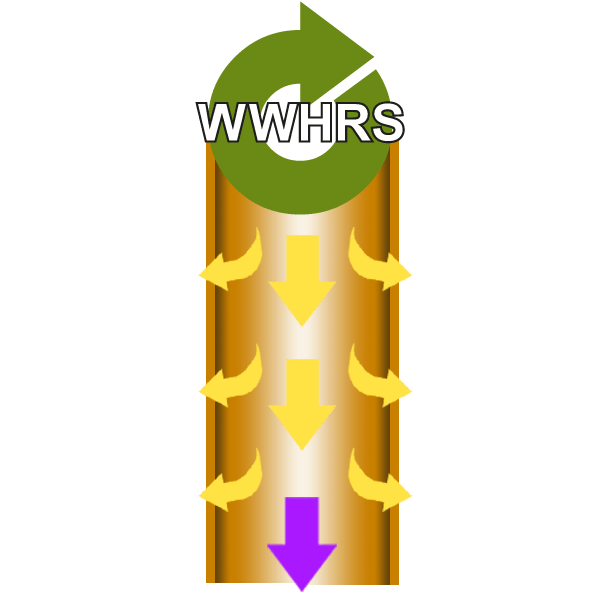

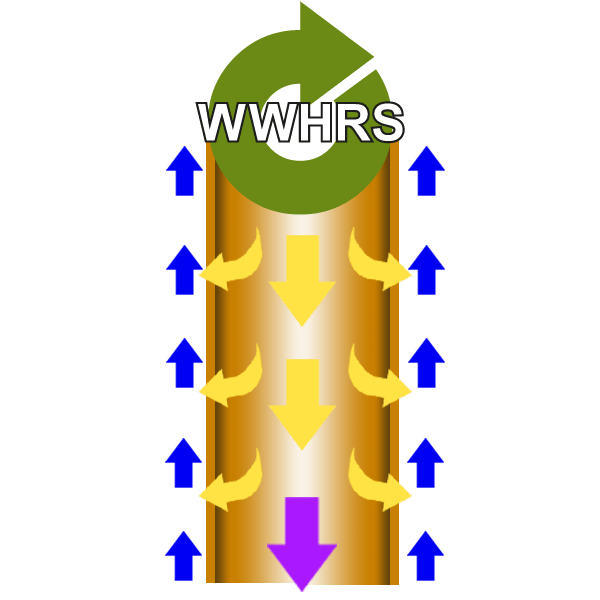

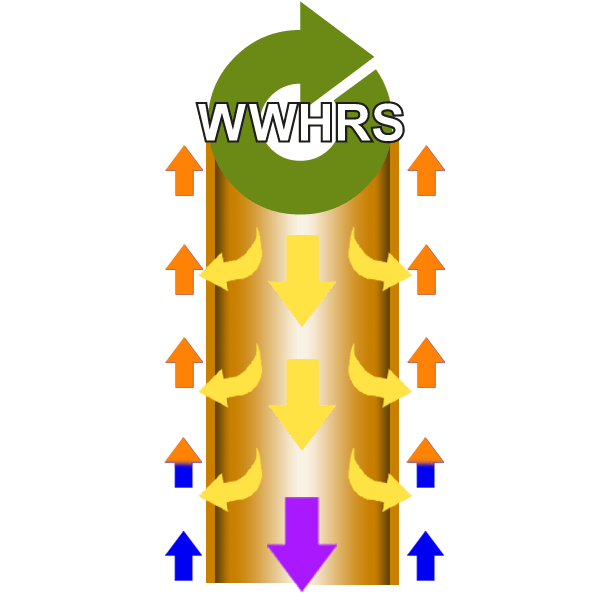

WWHRS is the abbreviation of Waste Water Heat Recovery for Showers. In the simplest terms a system or technology that uses the residual heat from the waste shower water to preheat the incoming cold feed that refills the system. Therefore, less energy is used to heat that water to the required temperature.

How it works

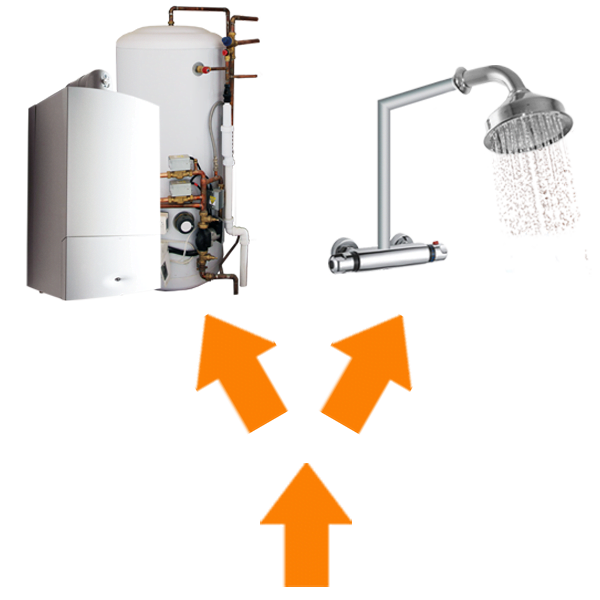

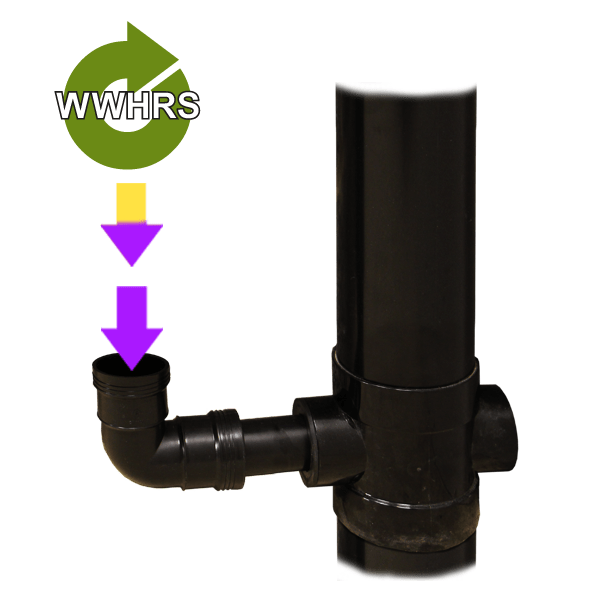

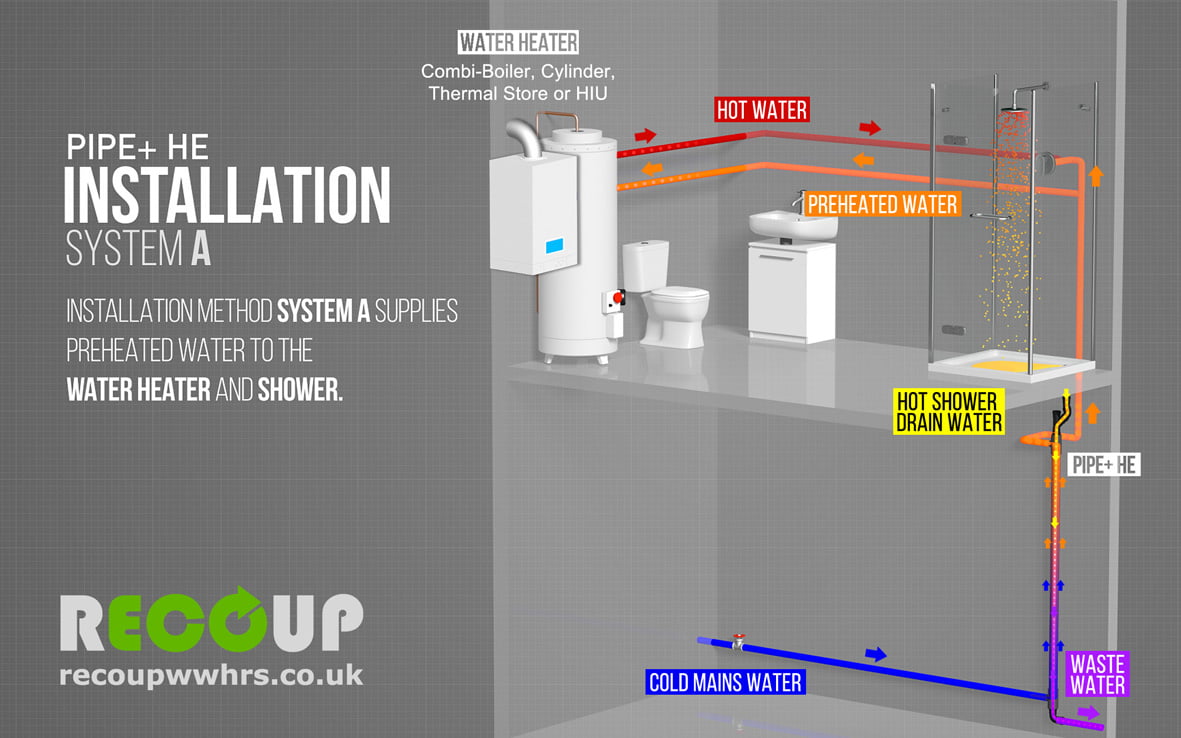

The animations below shows the Recoup Pipe HEX, vertical Waste Water Heat Recovery for Showers (WWHRS) and horizontal Recoup HeatDeck WWHRS. All Recoup WWHRS products follow the same principle. Shown how they work and the three installation methods for Waste Water Heat Recovery (WWHRS) with a TMV shower (Thermostatic Mixer Valve shower). Taking you through the three installation method configurations that can be installed (System A, B and C).

- System A – Preheated water is sent to the water heater and the shower

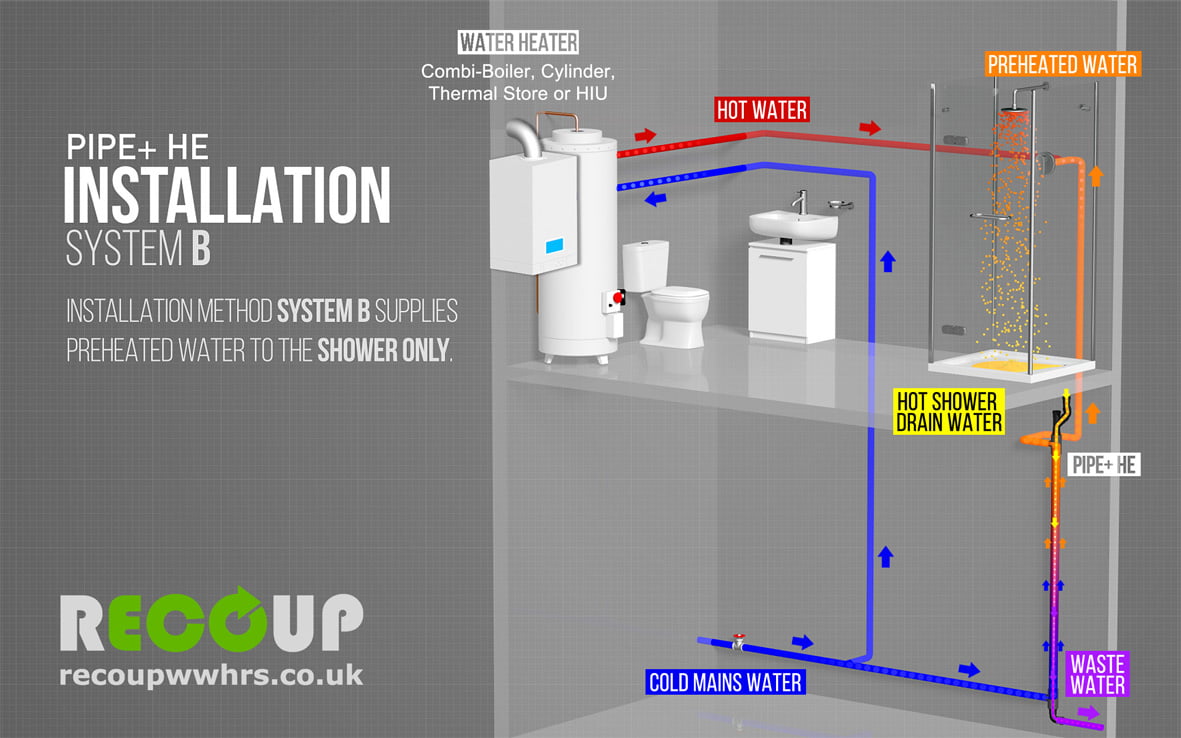

- System B – Preheated water is sent to the shower only

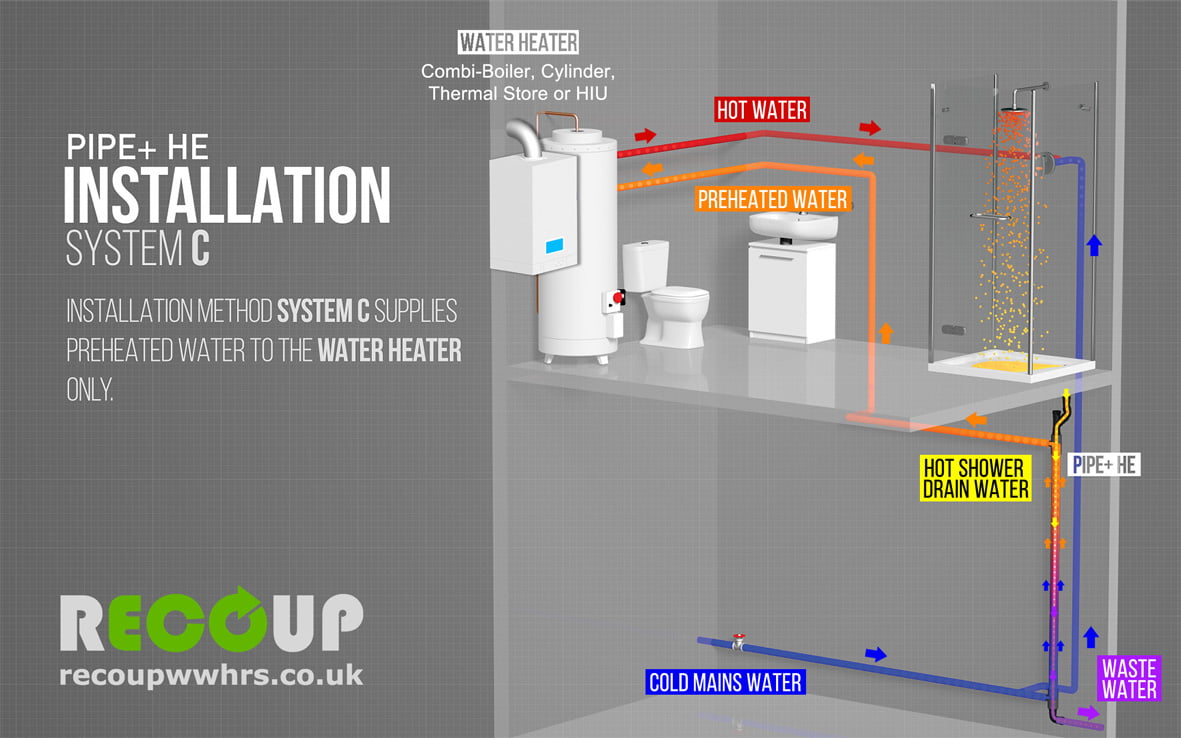

- System C – Preheated water is sent to the shower only

Recoup Pipe HEX Vertical WWHRS

Recoup HeatrDeck Horizontal WWHRS

How it works – System differences

Each system installation method has its purpose. System A is the most efficient and saves the most energy because both the water heater and the shower receive energy from the preheated water. This makes it the system installation method to use if you can.

System B saves less energy than System A or C but it is the easiest method to retrofit. You only need the preheated water to reach the shower which the WWHRS unit will be located near to. System B must also be used for any secondary systems because only one unit can be connected to the water heater.

System C saves less energy than System A, but more than System B. It is the least common but is recommended in specific layout situations. This can be when more than one shower is connected to a single WWHRS unit or when pipework distances do not allow System A to be installed.

If you would like to discuss which system installation method is the most suitable for your project, please contact us.