Waste Water Heat Recovery for Showers

The Micro House Scotland Project

Micro House Scotland is a pioneering self-build project by scientist and engineer Neil, who set out to prove that small-scale building doesn’t have to mean compromising on comfort or performance. His vision was to create a highly efficient project that pushed towards Passivhaus standards – all while delivering the kind of everyday luxuries that matter, like a warm, powerful, high-flow shower. Ultimately, this developed into a self-imposed challenge to create the highest flowing electric heated shower in Scotland, maybe even the UK.

Watch the full story from the installation of Pipe HEX RD Active to Neil’s results.

The Challenge: Comfort Without Compromise

For most UK bathrooms, conventional electric showers are capped at around 10.8 kW, which means they often struggle to deliver more than 4-5 litres per minute in colder months, far below the 10 L/min flow rate that makes a shower feel satisfying. In this project, the challenge was even greater: there was no room for a hot water tank, and Neil didn’t want to put extra strain on the main house combi-boiler. Add in Scotland’s chilly mains water – sometimes as low as 5°C in Edinburgh – and achieving a warm, powerful shower became even more demanding, as far more energy is needed to reach a comfortable 40°C.

The Solution: Smarter Showers Through Heat Recovery

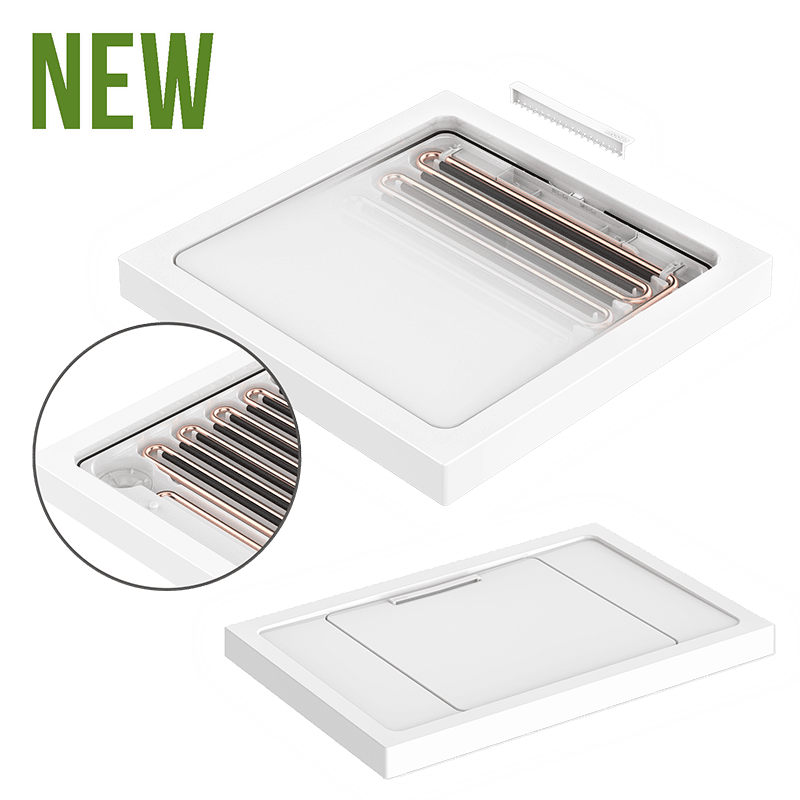

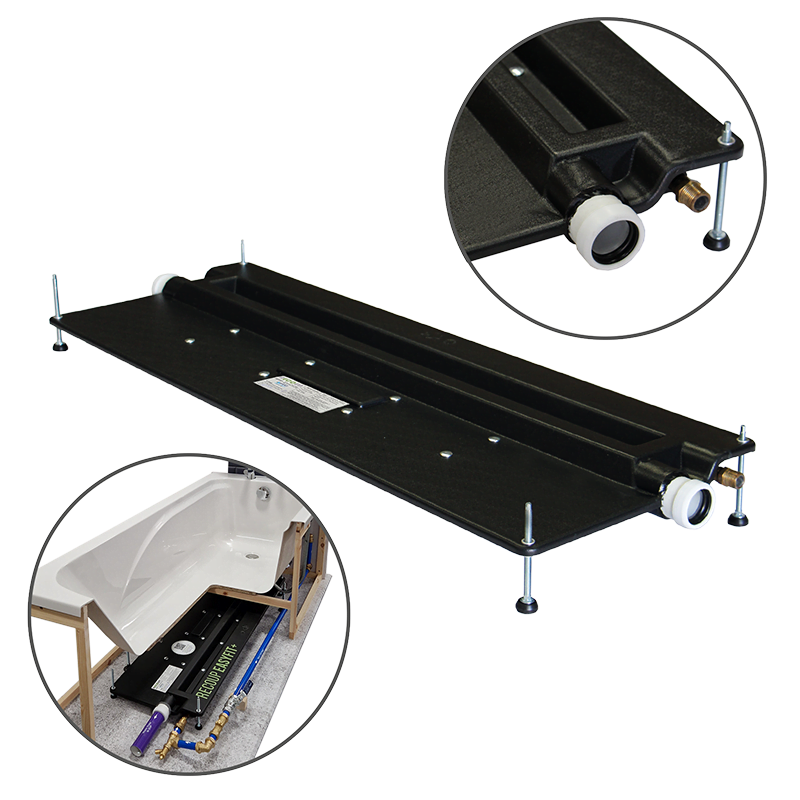

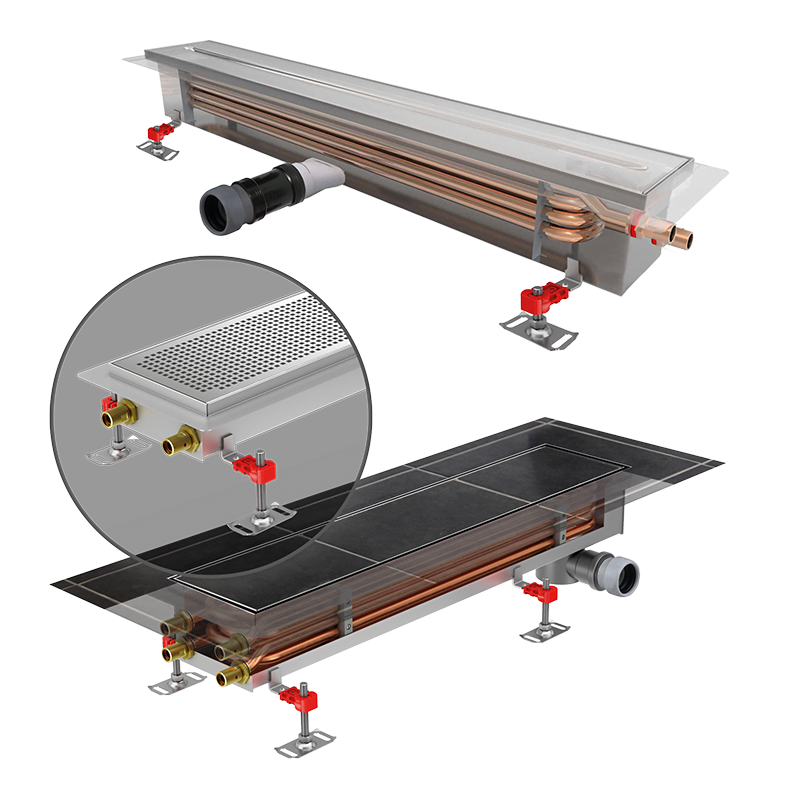

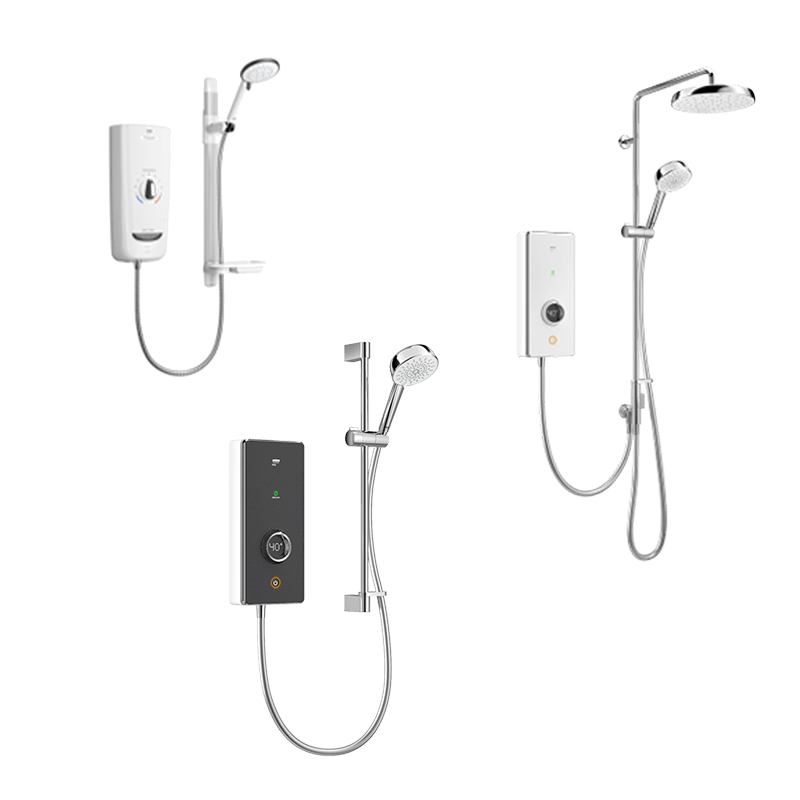

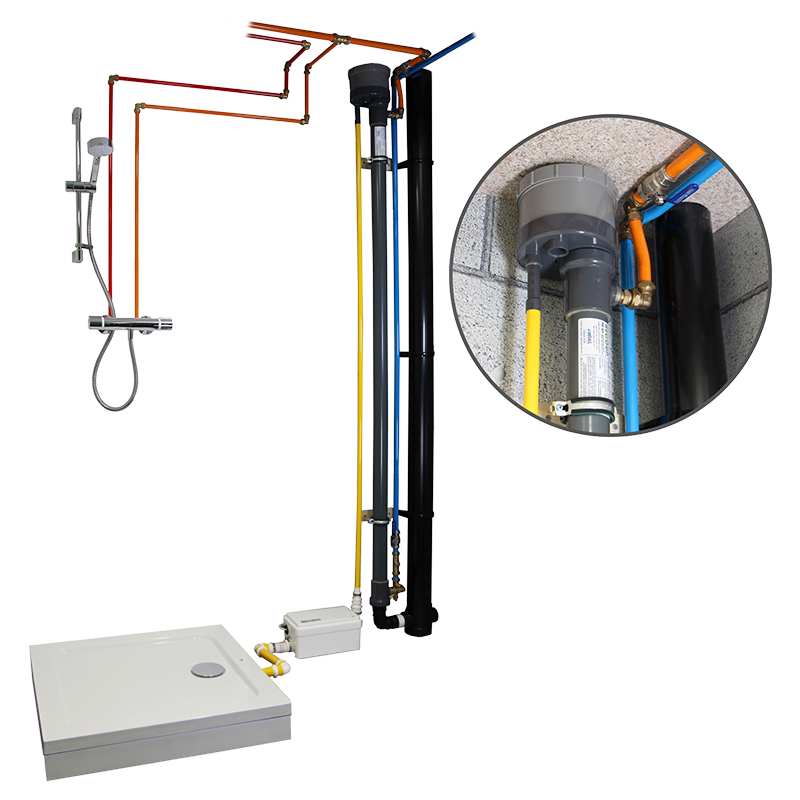

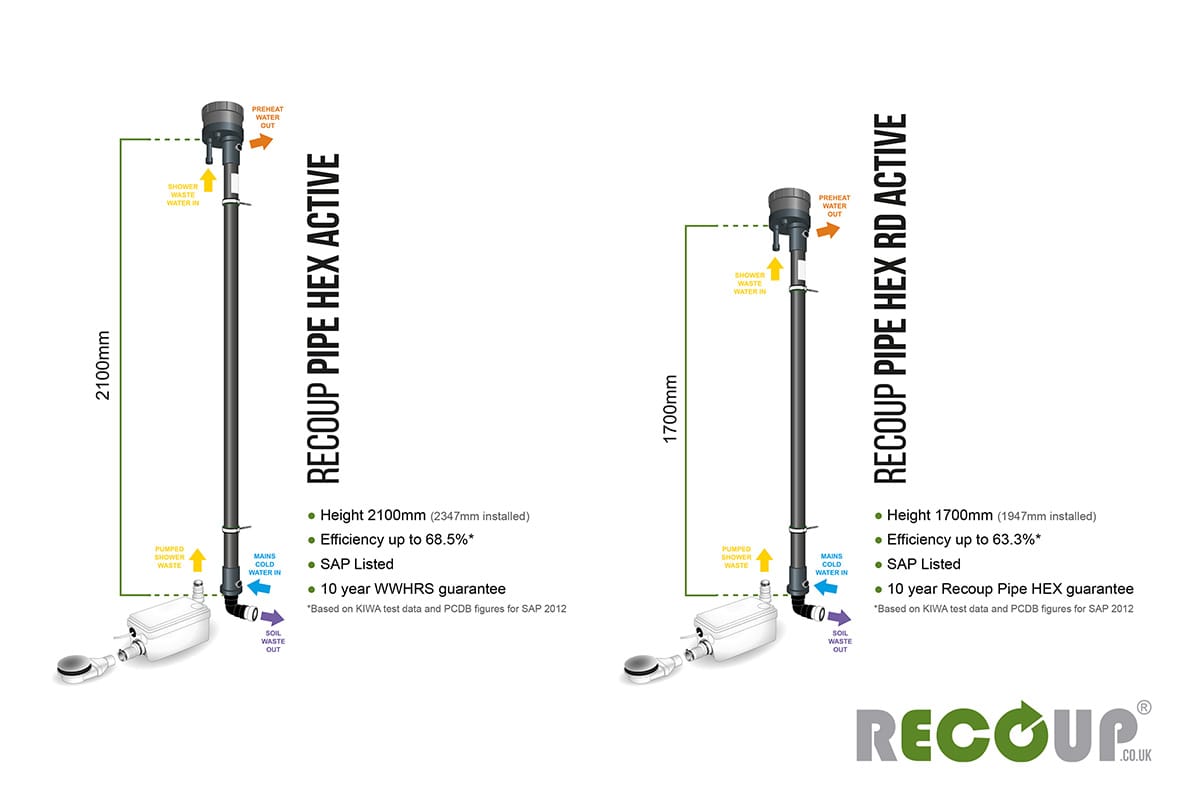

To overcome these challenges, Neil turned to Recoup Energy Solutions and chose the Pipe HEX Rd Active, a compact 1.7m waste-water heat recovery for showers (WWHRS) system with a built-in buffer and pump that can be installed on the same floor as the shower. By capturing heat from used shower water and feeding it back into the system, the Pipe HEX pre-heats incoming cold water with an efficiency of around 50–65%. The ultimate aim was to use the energy-saving heat recovery properties of the WWHRS to boost the performance of the electrically heated shower, which would not have been able to reach the desired showering temperature at such a high flow rate without it. Paired with a Stiebel Eltron DCE-S 10/12 Plus water heater, running at around 12–14 kW, the system could make the most of the warmer inlet water and deliver strong, consistent performance. To back this up, the plumbing and electrics were designed with plenty of capacity, using robust cabling, isolators, and balanced valves, ensuring the shower runs smoothly with no dips in temperature or flow.

The Results: Power and Efficiency Put to the Test

Recent tests show impressive performance across three flow-system variants with WWHRS:

*Efficiency = (Recovered Heat ÷ Total Heat to water) × 100

In earlier testing, before the WWHRS was installed, using pre-heated water from the main house boiler achieved a flow of around 8.8 L/min at just over 53 °C. Once balanced down to a typical showering temperature of about 40°C, this translated to roughly 12.6 L/min, a clear indication that higher inlet temperatures unlock much stronger performance.

“With the Pipe HEX Rd Active in place and the Stiebel Eltron heater tuned, I’m getting ~15 L/min @ 40°C – well over my 10 L/min target,” says Neil. “There’s no fluctuation, no lag, and the shower feels powerful from the word go. Although I’m using just 14.3 kW, the real win is how much recovered heat I’m getting back. It’s an incredibly efficient system and one I’ll be using in every shower build from now on.”

Efficiency Results

Based on testing on the live project, the efficiency testing showed very strong results, with the system achieving an overall efficiency of 46%* based on Neil’s initial testing. This means that just under half of the heat energy from the waste shower water was successfully recovered and reused to preheat the incoming cold supply.

* Some live testing achieved even higher efficiencies but the testing environment at time didn’t allow for heat loss from someone physically showering.

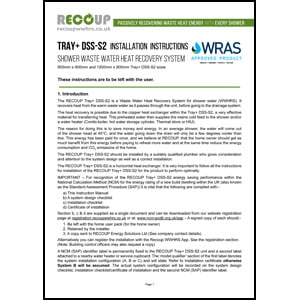

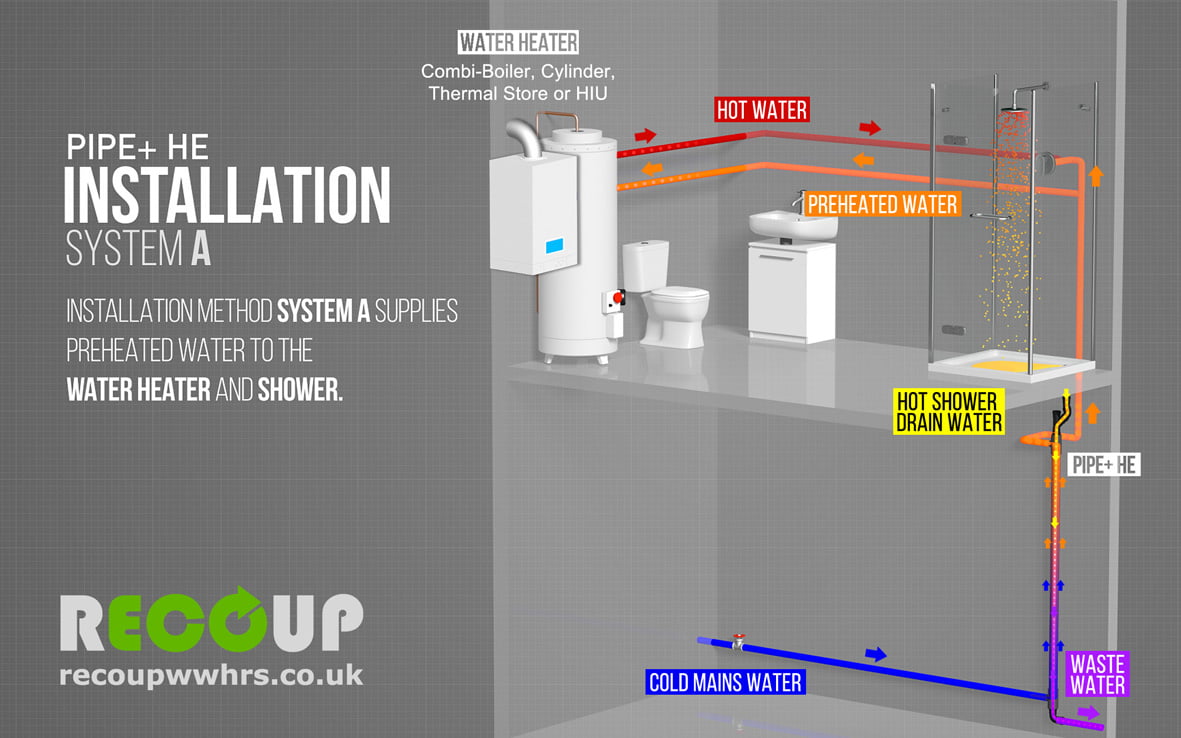

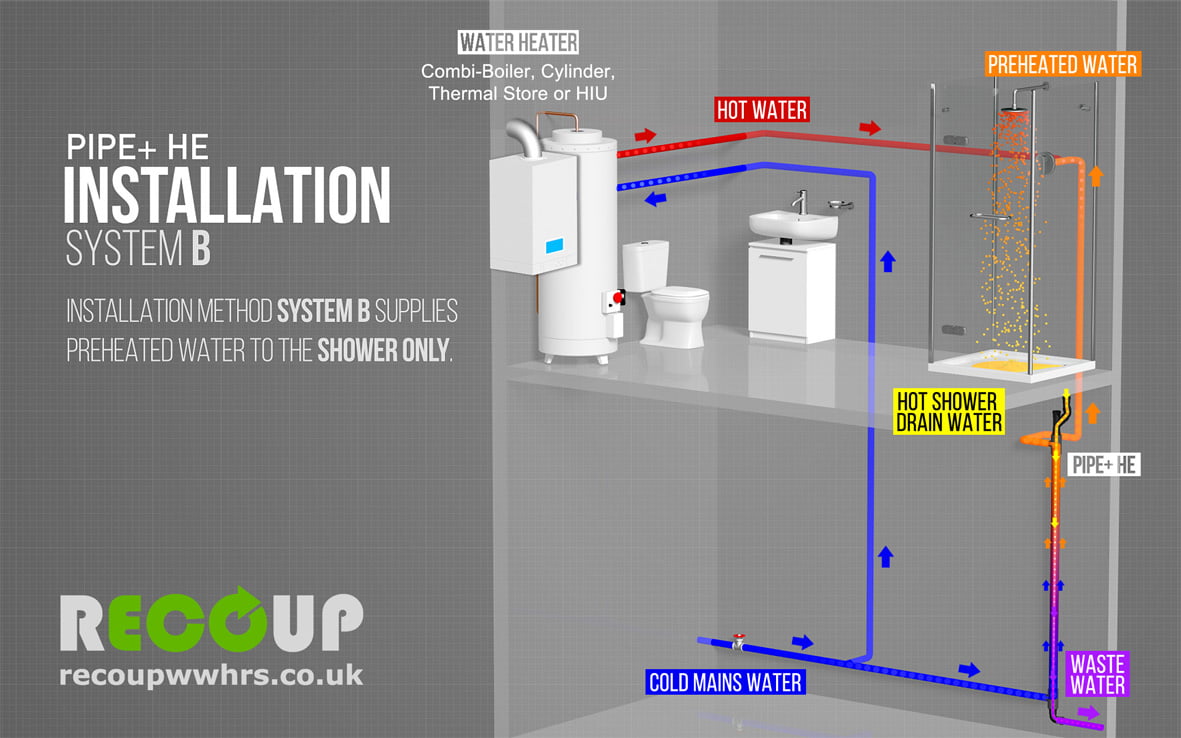

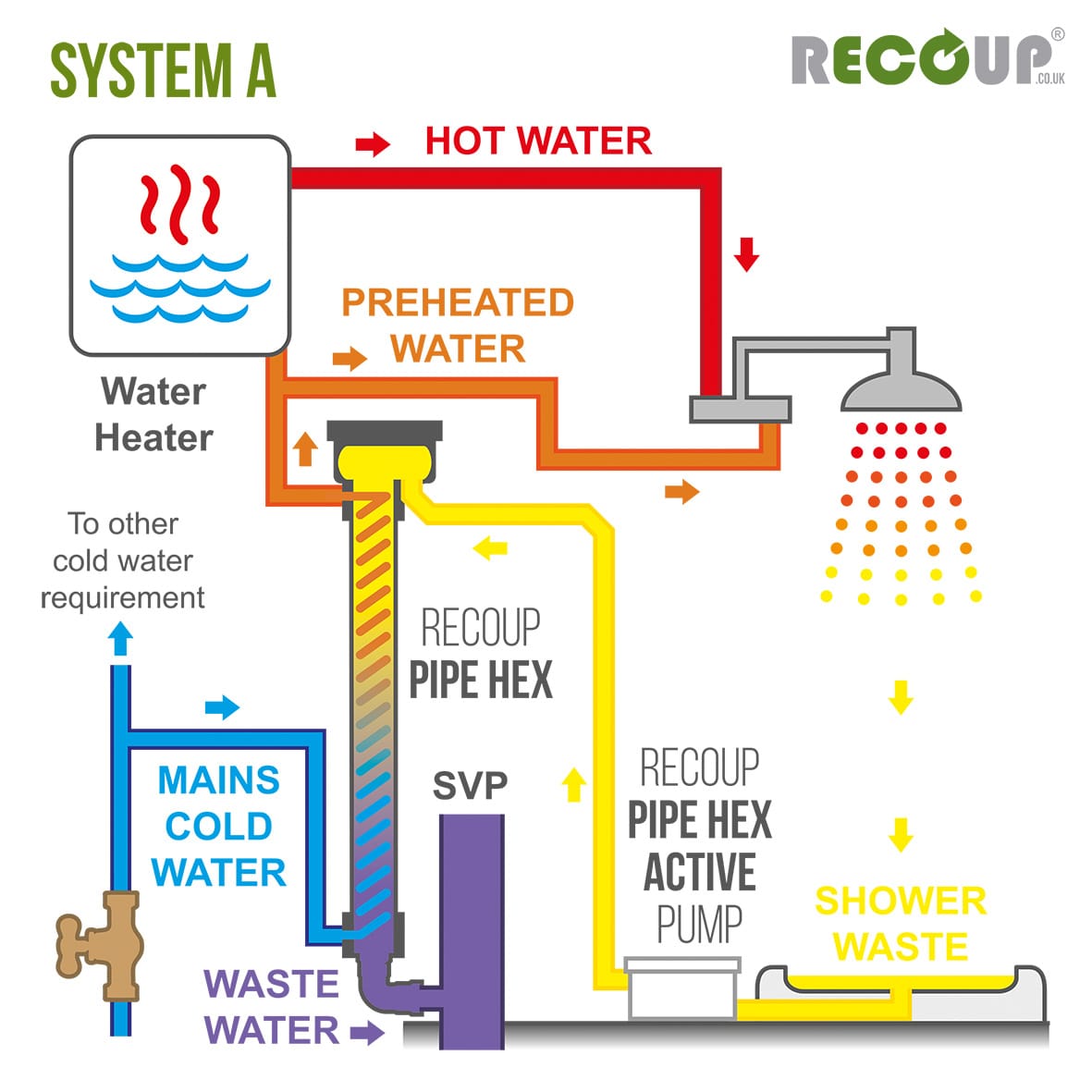

The preheated water generated by a WWHRS can be installed to feed just the water heater (System C); the cold side of the shower mixer only (System B) or ideally to both (System A) for maximum efficiency. System A consistently delivers the highest efficiency, as both the cold and hot feeds to the shower benefit from the preheated water supplied by the WWHRS to the shower TMV. System B (shower only – the easiest retrofit option) and System C (water heater only) are less efficient, as in each case only one feed receives the preheated water. While this project allowed all three configurations to be tested, in practice only one would be installed. Wherever possible, System A is recommended as the preferred setup, though its use can be limited by the relative locations of the shower, WWHRS, and water heater within the property.

The Outcome: Smarter Showers, Sustainable Living

The Micro House Scotland project shows how modern heat recovery technology can deliver comfort and efficiency even where space, supply capacity, and water temperatures create real challenges. By reusing heat that would otherwise be wasted, the Pipe HEX RD Active reduces the demand on the water heater, keeps energy use in check, and allows for high-flow showers that feel luxurious despite the project’s constraints.

Ellis Maginn, Head of Technical at Recoup Energy Solutions, says: “This project highlights the real-world challenges many homeowners face – limited space, restricted supply capacity, and cold mains water – and shows how WWHRS can make all the difference. By pairing the Pipe HEX RD Active with the right system design, we were able to help deliver a shower solution that combines high flow, comfort, and efficiency for the customer. It’s a fantastic demonstration of what our technology can achieve, even in the most compact of projects.”

For Neil, the results prove that building small doesn’t mean sacrificing comfort, and for others planning efficient builds or retrofits, it sets a benchmark for how innovative design and technology can make everyday living both enjoyable and sustainable. Learn more about the project Micro House Scotland project here as Neil continues testing.

More Case studies

Gilden Park Sports Pavilion, Harlow

Waste Water Heat Recovery for ShowersBuilding Greener Leisure Spaces with WWHRS Technology At the new Gilden Park Sports Pavilion in Harlow, Recoup’s Drain+ Duo HE Waste Water Heat Recovery Systems (WWHRS) are turning everyday showers into a source of energy...

Scaling Retrofit for Net Zero: The Role of WWHRS at NeRV

Waste Water Heat Recovery for ShowersDecarbonising the UK’s existing housing stock is one of the country’s biggest challenges in meeting its 2050 net-zero targets. Recoup Energy Solutions and the Net Zero Research Village (NeRV) are tackling this challenge by testing...

The Lovell Tomorrow Home featuring Recoup Pipe HEX

Waste Water Heat Recovery for ShowersRecoup’s shower waste water heat recovery system (WWHRS), the Recoup Pipe HEX, has been included in another leading housebuilder trial. This time for Lovell as part of its eco-friendly comparison trial at Cornish Park in...