Waste Water Heat Recovery for Showers

Recoup WWHRS now included in SBEM!

Oct 10, 2018 | Uncategorized

To provide the best experiences, we use technologies like cookies to store and/or access device information. Your personal data/Cookies may be used for personalisation of ads (learn more at Google's Privacy and Terms site). Consenting to these technologies will allow us to process data such as browsing behaviour or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Please note that many merchants use the Recoup Product Codes in the table below to order our WWHRS products. Specific merchants named below the table also have their own codes for specific Recoup WWHRS product types on their internal systems.

| Product | Description | Order Code |

| Pipe HEX | 2.1m High efficiency WWHRS Pipe (inc. Installation Pack) | R-HEX-01 |

| Pipe HEX Rd | 1.7m Reduced size WWHRS Pipe (inc. Installation Pack) | R-HEX-02 |

| Easyfit+ | High-efficiency Horizontal under-bath WWHRS | R-EZ-01 |

| Drain+ Compact | 800mm WWHRS Wetroom Drain | R-D-02 |

| Drain+ Duo (Quadratto) | 800mm WWHRS Wetroom Drain & Quadratto Cover | R-D-03-Q |

| Drain+ Duo (In-line) | 800mm WWHRS Wetroom Drain & In-line Cover | R-D-03-I |

| Drain+ Duo HE (Quadratto) | 800mm High-efficiency WWHRS Drain & Quadratto Cover | R-D-04-Q |

| Drain+ Duo HE (In-line) | 800mm High-efficiency WWHRS Wetroom Drain & In-line Cover | R-D-04-I |

| Preheat Tape | Tape to mark preheat pipework (Box of 10 Rolls) | R-WPIT-02 |

Code Item

D04046 Pack code for the Recoup Pipe HEX high efficiency WWHRS vertical pipe and Recoup Pipe HEX installation pack

(Pack code combines both required items, individual codes are D03670 for the Recoup Pipe HEX & D03671 for the Recoup Pipe HEX Installation Pack )

D00997 Recoup WWHRS Easyfit+ High Efficiency Retrofit Stand-alone WWHRS

D00996 Preheat Supply Identification Tape

Code Item

475633 Pack code for the Recoup Pipe HEX high efficiency WWHRS vertical pipe and Recoup Pipe HEX installation pack

(Pack code combines both required items, individual codes are 475630 for the Recoup Pipe HEX & 475638 for the Recoup Pipe HEX Installation Pack )

241111 Recoup WWHRS Easyfit+ High Efficiency Retrofit Stand-alone WWHRS

Code Item

RHEX1PA2 Pack code for the Recoup Pipe HEX high efficiency WWHRS vertical pipe and Recoup Pipe HEX installation pack

RECREZ01 Recoup WWHRS Easyfit+ High Efficiency Retrofit Stand-alone WWHRS

RCRWPIT1 Preheat Supply Identification Tape

Please refer to Recoup Product Code table above.

Contact us for Installation Support

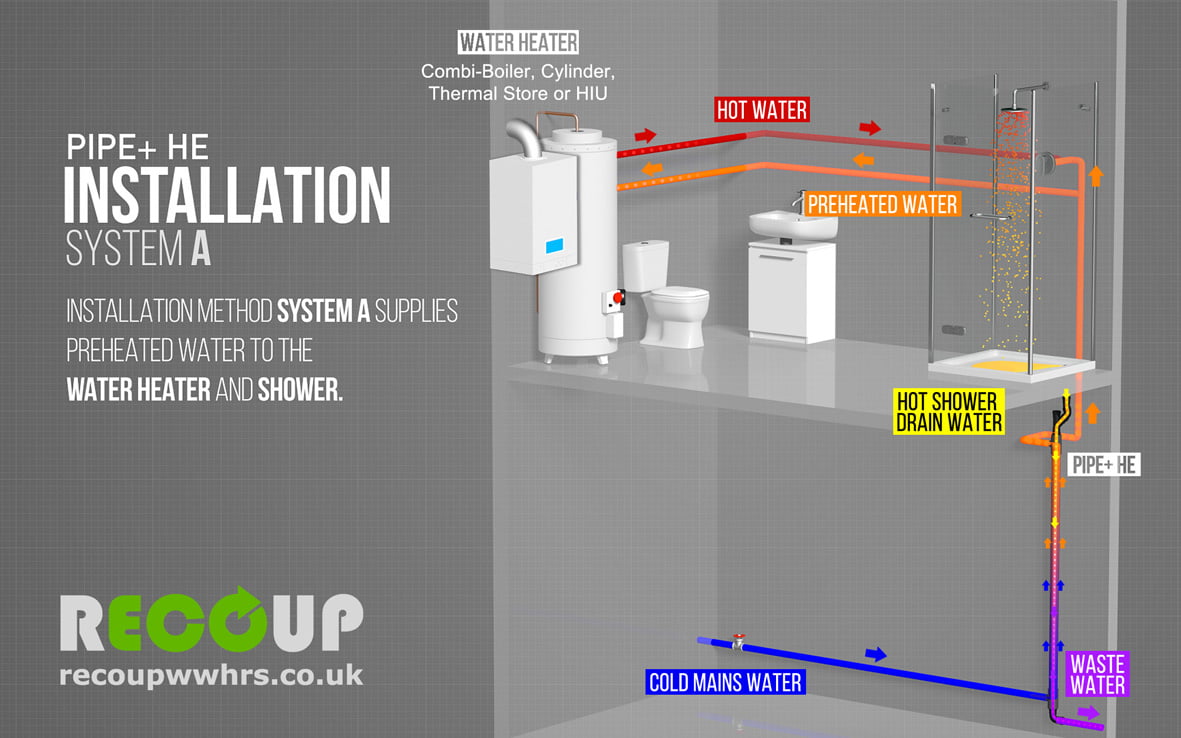

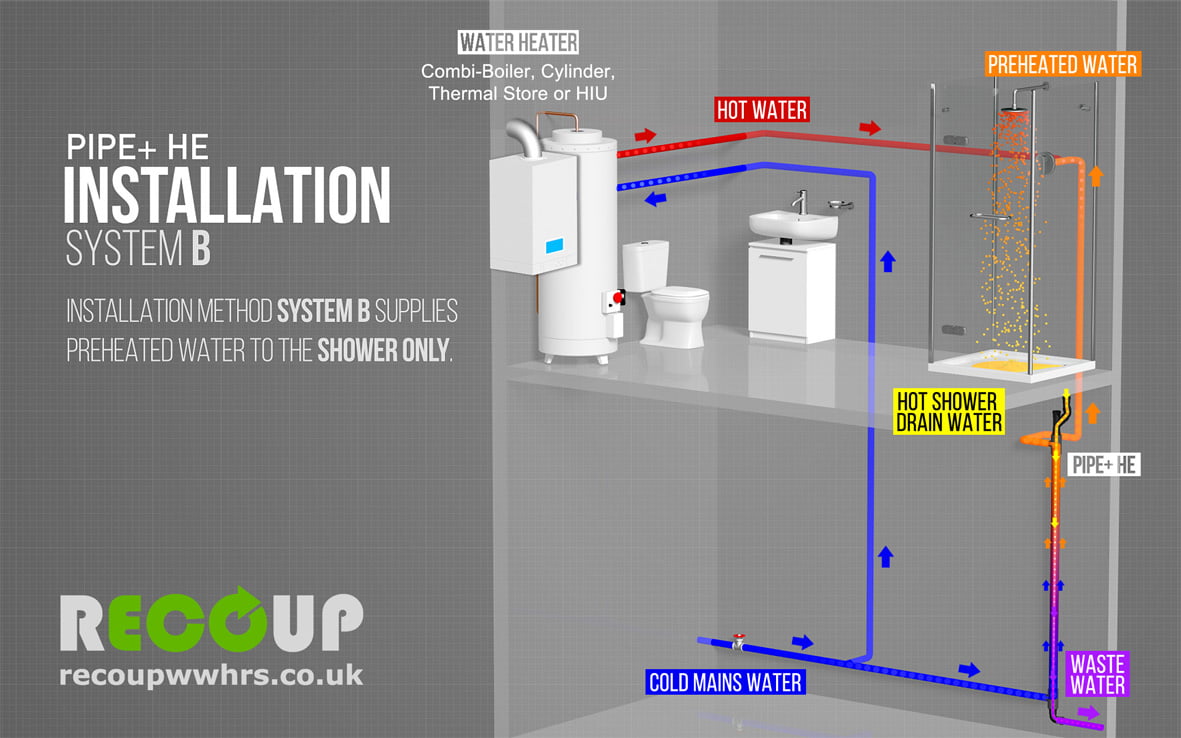

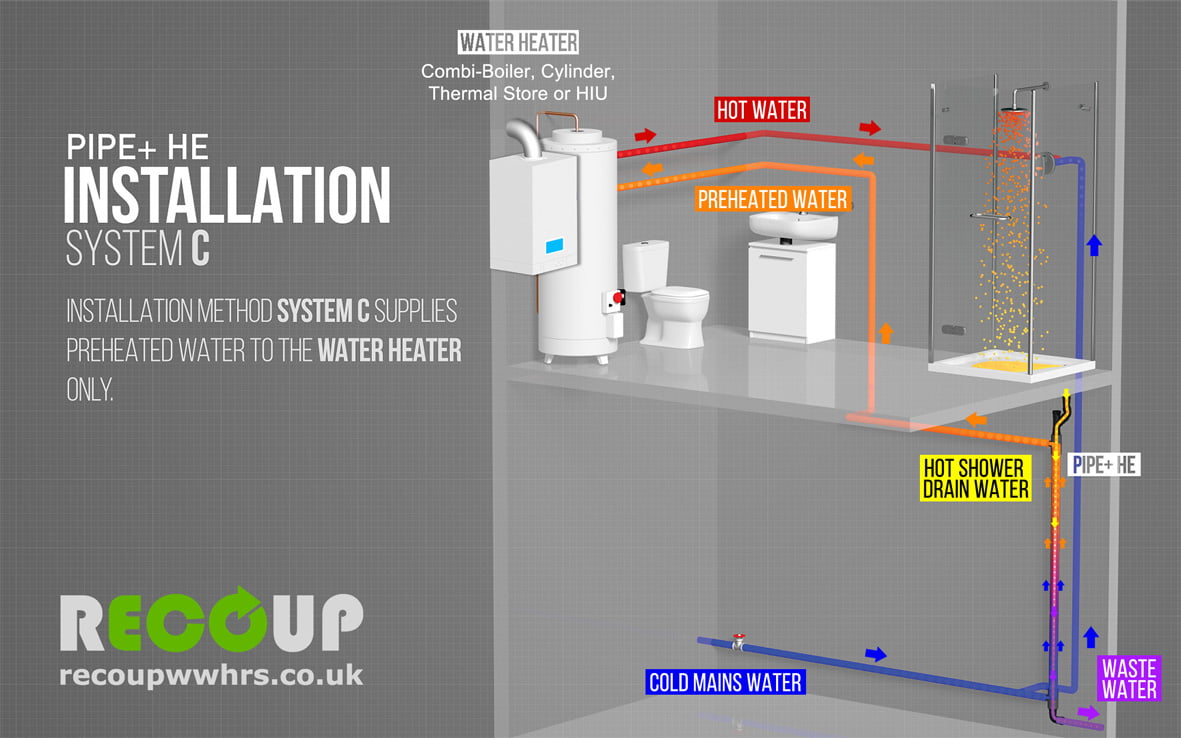

Installation Methods Video – System A, B and C

Q: How do you model in BREEAM?

Recoup WWHRS has been successfully used to gain ENE01 and ENE04 credits under BREEAM. Hotels, student accommodation and leisure centres can all benefit hugely from the addition of WWHRS. See our how to model in BREEAM article to see how WWHRS has been used successfully in other commercial projects or contact us to discuss how we can support you with your current project.

Q: How do you model in SBEM?

We are working hard with BRE to bring WWHRS directly into the SBEM model. However, in the meantime the have worked with leading consultants on numerous projects, and developed tried and tested work-arounds that allow designers and specifiers to incorporate WWHRS and model in SBEM, DSM or IES. See a worked example of this here.

Q: How do you model in SAP?

Take a look at our SAP page, or contact us. We’re always happy to take a look at dwelling or project plans and offer a tabulated list of WWHRS options, laid out so you can quickly and simply add them into your existing SAP models.

If you want to get an idea of how cost-effective WWHRS can really be in SAP, contact us, and we can work with you to identify the best options for WWHRS, and also which more costly or troublesome measures you may want to replace.

Q: Who do you supply to?

We are supply to national and regional house builders, and have an extensive client list {link}. We are sole supplier to the UK’s largest housebuilder Barratt Developments PLC, with sole supply to Barratt Homes, David Wilson Homes, and also to Bovis Homes.

Q: Does WWHRS work for baths and showers?

While WWHRS can be attached to a thermostatic mixer shower over a bath. It is not perceived to save energy when the bath is used, and drained. WWHRS works on the principle of cold water in, being pre-heated by the waste water going out. This recycling of heat energy, is the key to WWHRS energy savings. This cyclic flow is not available in a bath, as the water is flushed down the drain after the bath is filled.

Q: Do you have solutions for apartments or flats?

Yes. Where possible we would normally recommend the Recoup Pipe+ HE, as it is the most cost-effective system. However, any vertical WWHRS system needs to be installed on the floor below the shower it is attached to. Therefore, Recoup have a full range of Horizontal WWHRS systems, such as WWHRS integrated shower trays or wet room drains, or standalone horizontal systems such as the Easyfit+ HE

Q: Where can they be used?

Essentially, anywhere where showers are installed.

Vertical WWHRS sytems such as the Pipe+ HE are designed to located on the floor below the shower they service. They are ideal for new-build residential housing, and many commercial applications, such as hotels or student accommodation builds.

Horizontal systems such as the Recoup Drain+; Tray+ or Easyfit+ systems are designed to locate on the same floor as the shower they service. So, are ideal for ground floor showers; residential apartments; under baths or shower trays, and also for retrofit scenarios.

Q: Can you help with specification and design?

Yes. We’re more than happy to work collaboratively with designers ,SAP assessors and developers via floor plans etc to ensure our WWHRS is designed in, in the most cost-effective way.

While WWHRS is a relatively simple system to design-in. There are a few nuances that we can guide you on to ensure that the WWHRS solution that you use is the most appropriate, most installer-friendly and most cost-effective solution available.

We have the most experienced WWHRS technical team in the UK and are more than happy to help with projects big or small.

Q: What is it made from?

It is a 50mm copper heat exchanger tube, with a WRAS approved PVC injection moulded outer sleeve.

Q: What about legionella?

Recoup have been Legionella Control Risk Assessed for ALL products via ALL SAP recognised installation methods (System A, B & C) and each separate product and installation method has been deemed LOW RISK.

When installed as per our manufacturer instructions and the legionella risk assessment guidance (both of which are included with each product sold), the Legionella risk is deemed ‘LOW risk’ for all products in our portfolio AND all SAP recognised installation methods.

Realistically for any DHW product, there is no such thing as ‘NO risk’ once a legionella test has been carried out. The best achievable rating is ‘LOW risk’. Therefore it can be assumed that a correctly installed shower with WWHRS system offers no greater risk than correctly installed shower without WWHRS.

Any commercial shower system would be subject to L8 guidelines, and these would NOT be affected by the inclusion of WWHRS. For domestic systems there is not a requirement for L8 on showers (or any other legionella risk assessment as standard). Therefore based on our work with Legionella Control, the guidance (for both commercial and residential) you are seeing is primarily the guidance that would be issued for a shower with or without WWHRS, as the water contained within the shower hose (or pipework after the TMV) is held in a much higher risk temperature environment (c.40°C), than pre-heated water from the WWHRS (c.25-28°C).

WWHRS is unique as a hot water system component, in that it is one of the only solutions within the Domestic Hot Water industry that voluntarily opted to run legionella testing on its’ products (that includes ourselves and our UK competitors). That said, Recoup is the only company to have ‘LOW risk’ on ALL products and ALL Installation methods. This includes System B which is the most common method of installation in commercial systems with multiple shower outlets.

Also, it is worth noting that although WWHRS is a relatively new technology in the UK market (5-7 years), it has been installed and used without notable issue in territories like Canada and Europe for 15-20 years with no reported problems to date.

Installation notes:

a) Recoup are the only WWHRS products that have Legionella Control Risk Assessment in place for ALL systems and ALL installation methods. However, to maintain the lowest risk the following should be observed: the maximum pipe length from the pre-heat out (top of WWHRS unit) to thermostatic shower mixer(s) is 4.75m – this applies to installation via Systems A & B only).

b) SAP recommend that: the maximum length of pipe run from the shower waste water out, to the unit (WWHRS curved sleeve insert) should be < 3.0m. However, this is only guidance from SAP to ensure heat loss is minimised. If installation request a longer run that this, the installation would not necessarily fail SAP.

Q: Can the WWHRS be installed externally or in a garage?

No. WWHRS MUST be installed within the heating evelope of the building to be SAP compliant.

Q: Why is a double-wall so important in vertical WWHRS systems?

Whilst a single walled WWHRS heat exchanger can be used in the UK, to comply with Water Regulations it must have a trap installed downstream of the unit, not before it. Normally the trap would be installed under the bath or shower tray.

This can have the following results / issues particularly for, but not restricted to, vertical WWHRS systems…

These restrictions, costs, additional design and installation considerations, and possible future problems can simply be avoided by selecting a WWHRS system that has a double walled heat exchanger. The overall costs and possible future implications of the installation will be lower and end users can have greater peace of mind with the product that has been installed.

All Recoup WWHRS products are double walled heat exchangers.

Q: What is the significance of a double or single walled WWHRS heat exchanger?

The primary function of a double wall in an a WWHRS heat exchanger is to provide two layers of separation between the clean mains (drinking) water and the dirty shower waste (grey) water.

If a single walled heat exchanger is installed and the wall of the heat exchanger failed through perforation, manufacturing fault, or leaking. The shower waste water would come into direct contact with the clean mains water and can contaminate it.

A double walled WWHRS heat exchanger has a second wall to help prevent this from happening. European regulations (EN1717) require that double walls must be used to separate drain water and drinking water. UK Water Regulations do allow single walled products to be used, but additional design and installation requirements are required for them to comply.

All Recoup WWHRS products are double walled heat exchangers.

Q: Do Recoup products comply with UK water Regulations?

Yes. Unlike some other WWHRS pipe systems, we use a double-walled copper heat exchanger that directly complies with NEN1717 (EU/UK water regulations). Plus all products are WRAS listed too.

Q: Are all Recoup WWHRS products WRAS approved?

Yes, all of our WWHRS products are WRAS approved.

Q: Do you install?

No. we are a specialist supplier of WWHRS technology, rather than an installer.

Q: Do Recoup WWHRS systems replace the existing soil stack / SVP?

No. Our systems are designed to locate parallel to the SVP (vertical pipe systems) or within the shower waste pipe run (horizontal and integrated systems).

Q: What’s the difference between thermostatic and pressure balanced mixer showers?

Thermostatic mixer showers have an integral thermostat that regulates the water temperature to within a degree or two of that selected. Pressure balanced mixer showers provide a stable showering temperature despite fluctuations in water supply pressures. Digital mixer showers operate by heating water to a chosen temperature.

From: www.marketresearch.com/product/include/search-inside.asp?ProductID=9368415&page=20&kw=thermostatic%20mixer

Bath/shower mixer showers can be manually or thermostatically controlled.

From: www.marketresearch.com/product/include/search-inside.asp?ProductID=9368415&page=21&kw=thermostatic%20mixer

Q: Is a normal shower waste (with a water trap) ok between the unit and shower tray? No HepVo trap or vent required?

There is no specific requirement for a HepVo trap, and we normally suggest that a standard ‘water trap’ is perfectly fine. However, there may be a requirement to vent the waste drain pipe, if sufficiently long.

Part H, section 1 is applicable to sanitary pipework and is predominantly concerned with ensuring that the water seal or trap is not cleared during normal use, due to pressure differentials within the sanitary pipework.

However, as we (Recoup) are not normally involved in the specific M&E design of any given project it is impossible for us to give specific guidance or signoff for Part-H, other than to say “WWHRS must be installed with consideration to the most recent ‘Approved document – Part H of the Building Regulations’ for preventing the ingress of foul sewer gases.” As per our installation instructions.

The specifics of the sanitary pipe work layout and design would normally come from the architect, M&E of build services designer.

What we can advise is that according to Part H1 Foul Water Drainage, based on a 40mm waste pipe diameter, 3.0m maximum length from the shower trap to the discharge stack is allowed before venting of the waste pipe is required.

Q: Does the tee where the shower valve & Cylinder separate need to be as close to the shower valve as possible, so that when the shower is not in use the water flows through to the cylinder?

Not necessarily, but it is best practice to do so.

When the shower is not in use, the cylinder ‘recharge’ will draw through the WWHRS anyway, but the position of the ‘T’ shouldn’t really effective this. Where it may make a difference, is that the closer the ‘T’ is to the WWHRS unit, then the shorter the overall length that the pipe run will be from the WWHRS to the cold-side of the shower – and this is important to keep below 4.75m for Legionella Control risk assessment compliance.

Q: Tell me about pressure testing a Recoup WWHRS system?

Our WWHRS systems should be pressure tested with the rest of the installed system before use. DO NOT test over 10bar. If you are required to pressure test the DHW system over 10bar, then you should isolate the WWHRS completely.

Q: Tell me about commissioning a WWHRS system?

There is no specific commissioning required for WWHRS.

Q: Can more than one WWHRS unit be installed in a single dwelling?

Yes, multiple WWHRS units can be installed to multiple showers. However, ONLY one WWHRS system can be connected as System A (or C) ANY secondary WWHRS units MUST be installed as System B.

Q: Can Recoup WWHRS be installed to more than one shower?

Yes, but there are a few things that you should consider:

Two showers can physically be connected via System A. as long as the pipe run fro the WWHRS pre-heat out, to the cold side of the shower is within 4.75m and the waste pipe run from the showers to the WWHRS are ideally under 3.0m. However, consideration also should be given to the total combined flow rates of the showers. If the total flow rate is over 14-16 litres/min, then you will be getting a pressure drop of around 0.8bar, in the event of both showers being used together. Consideration should therefore be given to the incoming water pressure and any other elements that may cause pressure drop on the system.

If the combined flow rates of both showers are likely to be > 15 litres/min, then installting via System B or System C can be considered. This will give slightly lower SAP Score, but will allow for a higher total combined shower flow rate (as the pre-heat is now only going to either the cold side OR the hot water source, and both). Therefore total combined flow rates of 20-24 litres/min could be acceptable.

Q: What is the maximum length of 15mm pipe from the WWHRS unit to the Cold-side of the shower?

Recoup are the only WWHRS products that have Legionella Control Risk Assessment in place for ALL systems and ALL installation methods. However, to maintain the lowest risk the following should be observed: the maximum pipe length from the pre-heat out (top of WWHRS unit) to the cold-side of the thermostatic shower mixer is 4.75m.

Q: What is the maximum waste pipe length from the shower to the WWHRS unit?

SAP recommend that the maximum length of the waste pipe (40mm) from the shower trap to the WWHRS unit should be no more than 3.0m. This prevents any excessive heat loss between the shower and the WWHRS unit.

Q: Can you use 22mm or 15mm connections?

Yes, you can use either. There is a known pressure drop across the WWHRS exchanger, and this is not impacted by whether you use a 15mm or 22mm connection to the unit.

Q: What do I need to know about pressure loss and WWHRS systems?

There are known pressure drops across the Pipe+ HE (and all other WWHRS systems) at various flow rates.

Please see the Product Technical Data within the installation guide, or the product pages which includes a table for the Pressure Drop on the Main Water Circuit. (The example table below is for the Pipe+ HE)

| Shower Flow Rate @ 40°C ( litres/min ) | Pipe+ HE Pressure drop ( bar ) | ||

| System A | System B | System C | |

| 9.2 | 0.34 | <0.21 | |

| 12.5 | 0.45 | <0.27 | |

This known pressure drop, is not affected in any significant way by the 15mm to 22mm connections back and forth (although Please note that we supply with 1/2 inch BSP connection nipples, which must be used to ensure the PIPE+ HE outer casing is not damaged during installation) – The 1/2inch BSP can be connected to a 1/2inch female to 15mm (or 22mm) adapter/connection.

Due to the way in which WWHRS works, a pressure drop across the WWHRS unit is inevitable, however, it is worth noting that the PIPE+ HE is equal to or better than other equivalent systems available in the UK.

Q: Do you have a video installation guide?

Yes, we do for the Recoup Pipe+ HE

Q: Do you offer tool box sessions for installers?

Yes, we offer tool-box sessions for new installers. These are particularly useful for sub-contractors working on new developer sites. However, we also offer installation guides, walk-throughs and video installation guides.

Q: Do you offer training for installers?

Yes. Although WWHRS installation is very straight forwards, we offer installation guides, video installation guides, and tool-box sessions for installers, either on site or at your offices.

Q: Can the Recoup Pipe+ HE be installed horizontally?

No, any vertical pipe-style WWHRS system, such as the Pipe+ HE should be installed vertically. Installing horizontally would not allow the ‘falling film’ heat exchange that is required to maintain the tested efficiencies, and therefore energy savings.

Q: What fittings do I need?

The Pipe+ HE is supplied with an ancillary/installation kit, see below. Our other systems included the main water and waste connection points to connect typical plumbing fixings to.

In addition to the supplied kit and units the installer will also require 1x double check valve; 2 x isolator valves.

Q: Do you have installation guides?

Yes, see the links below for everything you should need, visit our downloads page for this and other information or contact us if you cannot find what you are looking for.

Recoup Pipe+ HE installation Guide and data

Recoup Pipe+ HE installation Guide and dataGuide to the installation, product details, performance and operation of the Recoup Pipe+ HE product.

Recoup Pipe+ HE installation process in pictures

Recoup Pipe+ HE installation process in picturesGuide to the installation process of the Recoup Pipe+ HE product shown in pictures.

Recoup Easyfit+ installation guide and data

Recoup Easyfit+ installation guide and dataGuide to the installation, product details, performance and operation of the Recoup Easyfit+ product.

Recoup Drain+ Duo HE installation and data

Recoup Drain+ Duo HE installation and dataGuide to the installation, product details, performance and operation of the Recoup Drain+ Duo HE product.

Recoup Drain+ Duo installation and data

Recoup Drain+ Duo installation and dataGuide to the installation, product details, performance and operation of the Recoup Drain+ Duo product.

Recoup Drain+ installation and data

Recoup Drain+ installation and dataGuide to the installation, product details, performance and operation of the Recoup Drain+ product.

Recoup Drain+ Compact installation and data

Recoup Drain+ Compact installation and dataGuide to the installation, product details, performance and operation of the Recoup Drain+ Compact product.

Recoup Tray+ DSS-S2 (900mm x 900mm & 1200mm x 900mm) installation and data

Recoup Tray+ DSS-S2 (900mm x 900mm & 1200mm x 900mm) installation and dataGuide to the installation, product details, performance and operation of the Recoup Tray+ DSS-S (900mm x 900mm and 1200mm x 900mm) product.

Q: Does limescale affect it – what about hard water areas?

No. WWHRS does not get in to the limescale depositing temperature range, as the incoming Cold Water Main is only preheated up to around 25-28 °C.

The outgoing waste is only recommended to be taken from the shower. The shower trap stays in place, and therefore will perform in exactly the same way as it would with, or without WWHRS attached.

The WWHRS exchanger is made from a smooth 50mm internal diameter copper pipe on the waste side, so is essentially like any other piece of copper plumbing pipework, and should be expected to last 40-60 years.

Q: Do Recoup WWHRS systems foul?

No. Firstly, unlike some other WWHRS designs, our WWHRS sytems do not take foul (black) water. We leave that to the soil pipes. Instead the WWHRS is located parallel to the SVP, and takes only the shower waste. This shower waste (minus most of its’ heat energy), is fed back into the SVP or Sewer pipe once it leaves the bottom of the WWHRS unit.

Q: What type of shower will Recoup WWHRS work with?

WWHRS is designed to work with Thermostatic mixer showers only. Only thermostatic mixer showers are allowed/recognised by SAP.

Q: Will WWHRS work with an electric shower?

While technically, yes it can. WWHRS is not recognised by SAP unless installed with a thermostatic mixer shower. This is required, as a thermostatic mixer will regulate/maintain the desired output temperature at the shower head, while adjusting the mix between hot and cold, as the WWHRS operates. A standard electric shower is not able to do this manually.

Q: Does it work with a bath?

Yes, as shower over a bath

Q: What are the benefits of WWHRS for plumbers and installers?

It’s quick and simple to install. It requires no maintenance, commissioning or specialist knowledge. There is no end-user interaction required, and it has no moving or mechanical parts. So generally nothing to go wrong once installed and pressure tested.

Q: What are the benefits of the Recoup Pipe+ HE for developers?

It is incredibly cost-effective in terms of SAP and Part-L compliance. It also has a large impact on SAP scores: A Recoup Pipe+ HE can generate a 6-9% uplift in SAP. Compare this to say, as standard solar thermal panel, and the Recoup Pipe+ HE will generally score higher in SAP, and cost 4-5 times less when installed.

Q: What are the benefits of WWHRS for homeowners / end-users?

Energy savings. It is estimated that showering takes up around 57% of the hot water that we generate. And in modern homes, hot water can represent as much of the energy budget as space heating ( even more in passivhaus and super insulated properties). So WWHRS can significantly reduce the energy cost for showering.

Q: Who do Recoup sell to, who are your customers?

Our main market is new build residential developers. However, we have products suitable for new build and retrofit; commercial and residential; self-build; passivhaus; hotels; student accommodation; modular construction….in fact anywhere, where there are showers.

Q: Where can I buy Recoup Products from?

We sell through all the main plumbers merchants and are stocked by Wolseley Group and Travis Perkins Group. Products are available from Plumb Center, PTS, City Plumbing, Grahams, Jewsons, Plumbase from over 6000 UK branches.

For more information on where to buy our products visit our stockists page.

Q: Is WWHRS SAP listed?

Yes, all Recoup WWHRS products are SAP listed for all three recognised installation methods (A, B & C)

Q: How much can WWHRS save?

Different WWHRS products have different energy recovery efficiencies and the overall energy savings per shower will be dependent on a number of factors, such as shower use frequency; shower time; temperature and flow rate. However, a Recoup Pipe+ HE installed as System A and used for 6.5 minutes per day, at 11 litres per minute and 5 times per day, would save around 2,519 kWh of energy per year. Payback on Gas would be around 3-4 years, and on electricity 1 to 1.5 years.

Q: I hear there are different ways of installing WWHRS systems, what are these?

There are three recognised methods of installing WWHRS…

System A which supplies preheated water to the water heater and shower

System B which supplies preheated water to the shower only

System C which supplies preheated water to the water heater only

Q: How does WWHRS work?

Simply put: WWHRS recovers the heat energy from waste shower water, and exchanges it with the incoming cold water main feed (CWM). The recovered heat energy is then used to pre-heat the incoming main by around 15-18°C. This temperature increase derived from heat energy that would normally flow down the drain, represents an energy gain, and work that the boiler of cylinder does not have to do. Therefore, a significant energy saving.

As well as feeding back to the hot water source (combi, cylinder, thermal store etc) the preheated CWM can also be routed to the cold side of the thermostatic mixer shower. This then means that to achieve the desired shower temperature (or 40 – 41°C) the shower mixer uses more free-preheated water, and less expensive hot water generated by the DHW system. Again, this generated further energy savings.

Watch our Pipe+HE Product and System animation below to show you the benefits and process of waste water heat recovery (WWHRS)